So, after my positive experience making .458" boolits from 45acp brass, I thought I would give making some for my 10.75X68 Mauser.

Keep in mind that this boolit can be used in the 404 Jeffery as a nice plinking or small game boolit.

Using fired 40S&W brass looks to be the logical start and tinkering with the core, I think I have come up with a pretty good boolit.

Just as I did with my .458s, I looked to use some standard reloading dies I already had on hand.

Evaluating case dimensions, I found that a 303 British die would give me a nice taper and a .423-.424" base diameter when pressed up into the die to the right spot.

My first go consisted of the brass and a 38/40 cast boolit as a core. This produced a light boolit with not much of a nose profile. What I was looking for is in the 300gr range with some sort of nose shape. I wasn't too particular on the nose profile just yet and found that a 6.5x54 die would work to shape the nose before pressing into the 303 die to reduce the body diameter.

Here is the empty brass. One with the 38/40 boolit as a core (which didnt fill the case very well) and one made with a 38cal lead ball inserted under the 38/40 slug. This is only pressed into the 6.5 die.

Once pressed into the 303 die, the desired diameter was reached.

Now. These two piece core models came out a bit under 300gr and shot shot pretty good.

I used 40gr of H4198 and a backer rod filler on these. That gave me 1840fps and no pressure signs or extraction issues.

I really wanted to get a better core and a nicer nose profile so I tried filling the cases with molten lead which I think helps to soften the case a bit although the non annealed cases seem to size and work just fine too.

Getting a consistent pour into a piece of brass is not as easy as it sounds but I was able to get a batch that are close to what I'm looking for. I have an idea that will make this part of the process much easier and more consistent - will report as it comes together.

For the nose, I tried lightly pressing the lead filled cases into my .451 paper patch swage die. This did give me a nice round nose profile which looks great but honestly, I don't know if it matters as far as accuracy at the ranges I would use this rifle. I think that for sure most folks don't have a point form die or swaging setup so sticking with the 6.5 die is a good option and I bet the flat nosed boolits that die produces would hit like the hammer of Thor!

I have found that I can skip the step of using the 6.5 die altogether if I use this die so that is what I am doing from now on since I have the option. Primarily for a nicer looking boolit but as I said, there is no difference in velocity and I doubt anything at the other end would notice...

This is what that looks like.

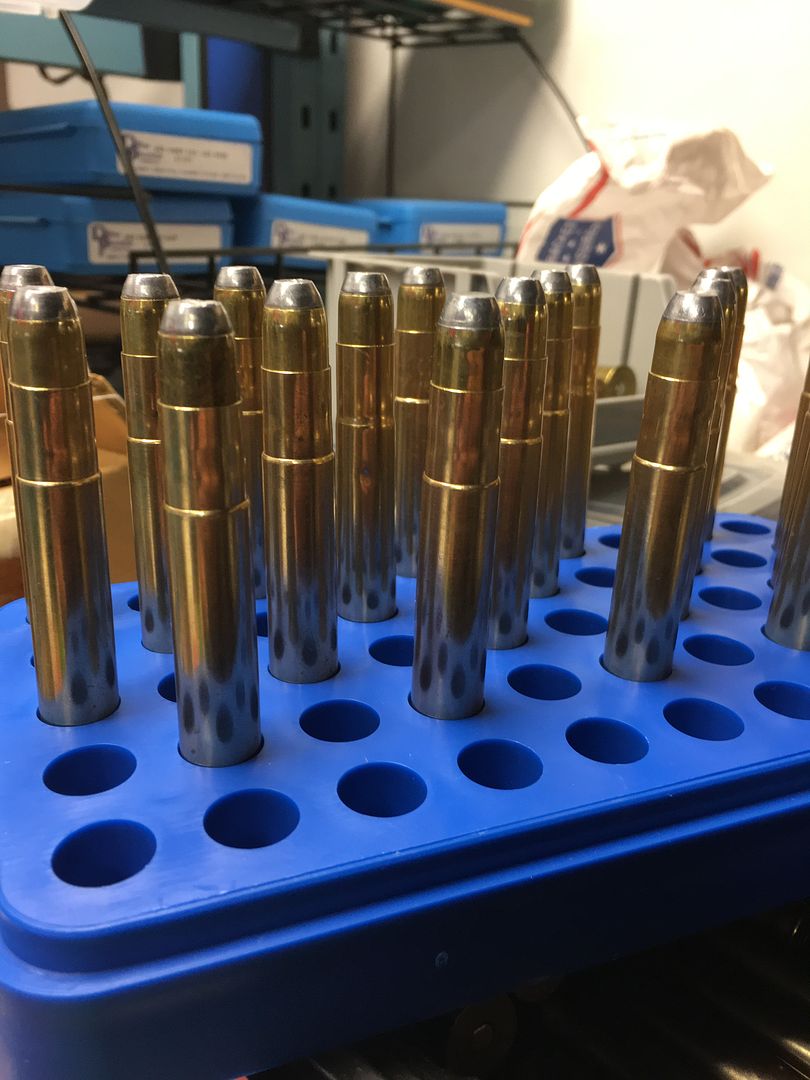

Here is the loaded cartridge.

And my 16yo son enjoying the results!!

|

|

|

Reply With Quote

Reply With Quote