G-Day Trevor,

Not everyone has an electrically powered coating machine,

a 10 tray drying/heating rack

a kitchen sized convection oven with dual PID's

and two casting machines.

What did you do the other half of the day

Cheers

|

|

|

G-Day Trevor,

Not everyone has an electrically powered coating machine,

a 10 tray drying/heating rack

a kitchen sized convection oven with dual PID's

and two casting machines.

What did you do the other half of the day

Cheers

[QUOTE=Gohon; Not as slick and shiny as powder coating but they pass all the tests. Think I'll take a chance and do a third coat just to see the results.[/QUOTE]

Gohon,

I am a little puzzled about "not as slick shiny as powder coat."

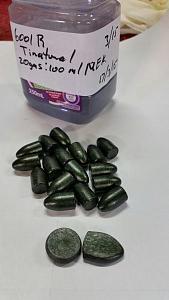

Attached is pictures of a couple of coated projectiles. They seem pretty slick

& shiny to me. I don't know how they compare to powder coating though?

My feedback page if you feel inclined to add:

http://castboolits.gunloads.com/show...raight-Shooter

Thanks Yall!

Hi-Tek, Mine look about the same as the pictures you posted and they are slick and have a shine to them. But, Powder Coating completely hides the lead underneath so you don't see any of the lead surface imperfections of the non sized parts. Don't know if that makes any sense or not.

Might just be the color (Gun Metal) that I used that resulted in a off color. Seems a couple poster stated that color seemed to have a mind of it's own as to what color it wanted to result in. Powder Coating also in my opinion is a thicker coat so that may be the reason. Haven't had a chance to test yet but I see no reason to think the Hi-Tek coating I did will not work just fine in my 9MM and 380.

Presently my thoughts are to run Hi-Tek only in pistol/revolver loads and stay with Powder Coating for the rifles which are 90% of my shooting. I'll certainly make up some rifle loads with Hi-Tek for testing but I know I can run Powder coated gas check cast up to 1900-2000 fps and plain base casts to 1500 fps with no leading and still get good accuracy. Don't know if Hi-Tek will do that but I'll soon find out.

Derek, I suspect Trevor is set up for mass production to sell his bullets. Don't think he was suggesting anyone copy his setup.

Last edited by Gohon; 08-06-2017 at 12:33 AM.

Even though I have the Commercial setup at the factory, I still coat, bake and size small batches at home with a benchtop convection oven, a hand swirled plastic pail and an upside down Lee press to size on.

All the testing for HITEK is done at home.

All the bullets for my personal use are done at home.

It helps keep me sane...lol

Hooroo.

Regards, Trevor.

Australia

[QUOTE=Gohon;4118459]

Presently my thoughts are to run Hi-Tek only in pistol/revolver loads and stay with Powder Coating for the rifles which are 90% of my shooting. I'll certainly make up some rifle loads with Hi-Tek for testing but I know I can run Powder coated gas check cast up to 1900-2000 fps and plain base casts to 1500 fps with no leading and still get good accuracy. Don't know if Hi-Tek will do that but I'll soon find out.

Gohon,

I found a post from 2014, I hope I don't get in trouble quoting this post. It is directly in relation to your concerns about velocity and rifle used ammo when using Hi-Tek Coatings.

Hi,

I have exceeded jacketed bullet velocity with my Contender 23" bull barrel in 223 Rem. I used linotype and then heated to 35 bhn. Be sure to install the gas checks before heat treating. I used short bake cycle for the first 2 coats. Do make sure that each coat passes the acetone wipe test before an additional coat is put on. I baked longer for the third coat and water quenched the boolits. I was able to keep the bhn at 32 bhn this way. I shot these to 3,619 fps with accuracy around 2" to 2 1/2" at 100 yards.

This was a test to see if the high velocity was possible.

I have also shot the Lee 200 gr RN GC in my Savage 30-06 to around 2,600 fps with the same alloy as above.

For slower velocities linotype or heat treated alloy will work. I use the chart in the Richard Lee Second Edition Manual as a guide as to how hard the alloy should be to obtain a specific velocity. This seems to work well.

Gun condition and powder choices can have a direct bearing on the end results. I lean toward slower powders for the cartridge. I used H4895 in the 223 Rem and H1000 in the 30-06. Boolits on the heavy side tend to work better in the rifles.

Your choice of coatings should work fine as I have used several different ones.

Last edited by HI-TEK; 08-06-2017 at 09:03 AM.

EVERY GOOD SHOOTER NEEDS TO BE A HANDLOADER.

NRA Cert. Inst. Met. Reloading & Basic Pistol

I thought Trevor would weigh in on this one. The gunmetal is a finicky color. I think I read somewhere that you need to determine the minimum bake time for your oven required to pass the smash and rub tests then add 1 minute for insurance, and be absolutely shure your oven is holding @ 400*

When this product was first supplied, it was attacked mercilessly as not complying to instructions and results. I had to re-test it 3 times with Trevor, Each time results were exactly as required and advertised.

What became apparent is, that users may have not adequately mixed coating mixture well enough just prior to applying coating mixture.

Second, the oven used, had great deficiencies with temperature variations of plus or minus 50C from set temperature, and no internal air circulation.

That produced various shades of dark Green.

When users checked out their applications and ovens, there was better and more consistent results.

The product should look similar to attached photos.

I use a fan to cool & dry my bullets between coats. This speeds things up & keeps the process moving. It isn't like I have all day to do this stuff.

EVERY GOOD SHOOTER NEEDS TO BE A HANDLOADER.

NRA Cert. Inst. Met. Reloading & Basic Pistol

I have never had issues with the gunmetal colour.

The 2 photos above are both different batches baked at different dates and times in the same oven with the same methodology.

No problem.

Hooroo.

Regards, Trevor.

Australia

G'Day Joe.

I've been curious about this, Do the once baked boolits need to be completely cool before the successive coating?

Logic dictates that the warmer the substrate the faster the solvent evaporates in the tumbling process.

But if you can get an even coat on the boolits and get them in the dry/bake tray before the sound starts to change

(about 10 seconds) is there a chemical reason this wouldn't work?

I like them to be cool to the touch before applying the second coat.

Out of the oven for 1st bake, under fan for 5 minutes. apply 2nd coat. Easy.

Hooroo.

Regards, Trevor.

Australia

Yeah I dont have a fan in my oven, but it seems to keep temp well and appears to heat evenly based on the uniform color of the bullets. When I tried my ****** toaster oven the bullets in the middle of the tray turned different color than the rest. I did some copper red today and that color came out like I expected.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |