The RCBS 124 gr RN is the cats meow if you get lucky and have one that casts .357-.357( have one!). Also, the RCBS 125 gr RN GC boolit is also the bomb and is pure cheating.

|

|

|

The RCBS 124 gr RN is the cats meow if you get lucky and have one that casts .357-.357( have one!). Also, the RCBS 125 gr RN GC boolit is also the bomb and is pure cheating.

The great thing about the Lee 356-120-TC is that they drop at the perfect size for 9mm, a bit over .357. I just pan lube and load up. Every problem I've had with boolits in 9mm has come from the "correct" .356 diameter. Just a few days ago I loaded some old factory Speer 124 grain lead round nose with 3.3 grains IMR 700X for practice. Out of both my Ruger SR9C and Kel Tec PF9 it was keyhole city, both guns were caked with fouling afterward. Both of them shoot better than I can hold and produce little fouling with .357 boolits. The rest of those crappy slugs got turned into more 356-120-TC last night!

Currently casting and loading: .32 Auto, .380 Auto, .38 Special, 9X19, .357 Magnum, .257 Roberts, 6.5 Creedmoor, .30 WCF, .308 WCF, .45-70.

I work at a gun store, and I have had the chance to look over G2,G3,G4 glock booklets Where does it say not to shoot lead cast bullets? can someone take a picture and post it?

43 PU

BTW my 21 G4, 35 G4, 34 G4 LOVES lead cast boolits around 12 BHN

My Glock manual says not to use "unjacketed" bullets, it does not actually prohibit lead boolits per se. I'm really enjoying my 19 gen. 4. Last night I put some more Lee 356-120-TC downrange out of the Storm lake barrel. This pistol is definitely more accurate than I can hold. I use the original front sight and the Glock adjustable rear, with the elevation all the way down. I also find that trigger finger placement makes a huge difference in group size. If I use my finger tip and a slow, firm press like its a rifle trigger I am rewarded with small groups that are point of aim. If I put too much finger on the trigger and pull it through the whole way like a double action revolver I print much larger groups to the left. After polishing the internals my trigger feels like a single action with a fair amount of takeup and overtravel, pretty good for a defensive pistol. I may end up getting a generation 2 Glock 19 for a fall/winter CCW.

Currently casting and loading: .32 Auto, .380 Auto, .38 Special, 9X19, .357 Magnum, .257 Roberts, 6.5 Creedmoor, .30 WCF, .308 WCF, .45-70.

Has anybody shot any of the Lee Tumble lube boolits through a stock glock 19? How did they perform?

Practice releasing the trigger only far enough to feel the reset, then press again. This gives you a single action feel for all subsequent shots after the first. It should give you better accuracy, as well as let you fire a little more rapidly once you get a feel for it.

Bersa, I have not been very happy with any tumble lube designs in the Glock barrels. I think they just don't have enough un-interrupted bearing surface to resist skidding and gas cutting in these polygonal bores, except at real low pressures. They are better when powder coated, but still not as accurate as their equivalent traditional groove designs, in my experience.

Ferguson,

If you are right handed and your groups are low/left then what is occurring is when you squeeze the trigger the other three fingers on that hand are also squeezing. That tends to pull the pistol down/left for a righty, up/right for a lefty.

I love my gen 2 19s. The only Glock I like better are the gen 2 23s.

Cat

Cogito, ergo armatum sum.

(I think, therefore I'm armed.)

In that case, I really recommend powder coating, with the shake-n-bake method, which is essentially the same as tumble lubing except you bake the finished product in a toaster oven, instead of setting them out to dry. You'll get better results, with zero leading, and no extra equipment, except a toaster oven. Powder is cheap and lasts a long time.

Its been months since I bought the book, "How to scam people online". It still has not arrived yet!

"If the human population held hands around the equator, a significant portion of them would drown"

Just "Google" the forum!

http://castboolits.gunloads.com/show...oating-Boolits

I've had good results with TGIC Polyester powders from Powder Buy The Pound, and also from ebay seller dmc2powder. I do not recommend Harbor Freight powders; they are cheaper, but results aren't as good. A half pound of good powder is enough for several thousand bullets at least. I did a writeup on the shakenbake method a while back, I'll dig it up and re-post it here.

Copy and paste of my writeup from a different forum:

Thought I'd share my recent experience here with coating my cast bullets to eliminate bore fouling. This is by no means my own idea; guys in Australia and parts of Europe have been able to buy commercially coated cast bullets for a while now. Here in the US though, it's just now catching on, with a lot of experimenting how to do it best.

I'm dry tumbling my cast bullets in ordinary powder coating powder, and baking them, to get a reasonably even powder coat over the whole bullet. This means no exposed lead, no lead/bore contact, and no leading (or any other metal bore fouling, just powder).

The whole process is pretty easy, about the same effort as tumble lubing, but without the wait time for it to dry. My process, from melting pot to loaded ammo, is as follows:

- cast bullets

- dry tumble in powder

- bake 15 min

- cool 5 min

- repeat tumble & bake

- push-through sizer

- load ammo

The powder I'm using is TGIC Polyester from Powder Buy The Pound. I ordered a bright green, and a iridescent green.

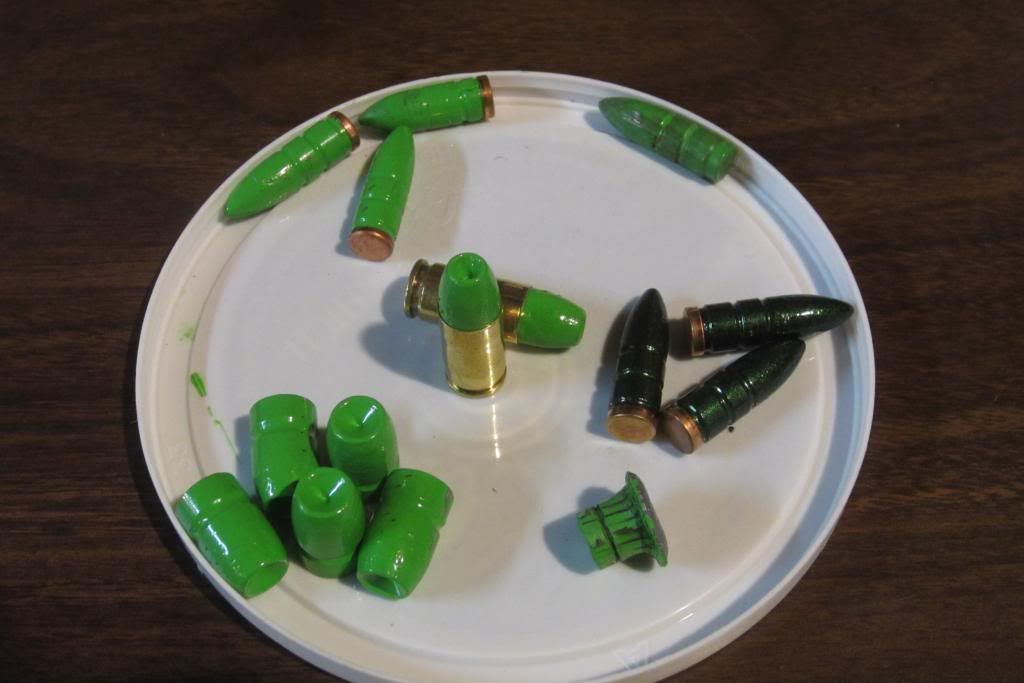

I use a plastic yogurt container to tumble the bullets. With dry tumbling, you can't really get too much, the excess powder just stays in the bottom. I shake the container by hand until the bullets are evenly coated. This is the second coat on these bullets:

Then dump them out in a tray. A bit of metal screen on the bottom keeps the bullets from getting a flat spot in the coating where they touch the tray. Don't touch them, the powder comes right off at this point.

After baking for 15 minutes (the directions say 10 minutes, but my garage is cold and the toaster oven is small)

Sized and ready to load

More bullets.

- The .30 cal rifle bullets are working fine at 2000 fps in my 300 Blackout; trying them in my 308 next. The one at the back right was recovered from a subsonic load; it penetrated about 18" of alder log, and only shed a little of the coating on the nose.

- The expanded bullet in front is from the loaded rounds in the center - 9mm 125gr Mihec mold, with modified shallow hollow point pins, 6.0gr WSF for ~1220 fps. This load needed aluminum gas checks to prevent leading with traditional bullet lube, but now the coating is completely intact around the base and bore contact surfaces with no bore fouling at all.

-The 200gr 10mm Mihec bullets on the left show how the hollow points get nicely coated too.

Do you size them before you apply the powder or after?

Bob

Its been months since I bought the book, "How to scam people online". It still has not arrived yet!

"If the human population held hands around the equator, a significant portion of them would drown"

Looks like they are sized after the powder. What temp do you set the oven to?

Looks like it but it seems odd to do so.

Bob

Its been months since I bought the book, "How to scam people online". It still has not arrived yet!

"If the human population held hands around the equator, a significant portion of them would drown"

Size after; there's no reason to size before, it would just be an extra step that's not helpful. You want some compression of the powdercoating during sizing to form a smooth slick surface.

Different powders require different temps, but most of the stuff I use needs to be baked at 400* for 10 minutes. I bake for 15 minutes, just to make sure I have 10 minutes at temp, longer is fine too. You do need to verify the temp with an oven thermometer since most toaster ovens don't have a very accurate dial (just like a Lee melting pot!).

Yondering, Why does the powder stick to the bullet prior to cooking? Seems like it would only leave a slight dusting.

Rule 303

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |