Twice now I have melted batches of bullets while attempting to PC them, and I am wondering if I am doing something stupid. I look forward to comments.

I started out with a used conventional toaster oven with the manufacturer's temperature dial. I became convinced that at some point during my use of this oven, something on it broke such that it was no longer heating properly. In order to rectify this, I wired all the elements to be always on, stuck in a thermocouple, and attempted to use my PID for temp control. This immediately melted a batch of bullets, due to my attempt to use a very short, unobtrusive TC. I wired in a longer TC probe and successfully PCed additional bullets, although the temps would drop rapidly and take a long time to equilibrate when new trays were put in.

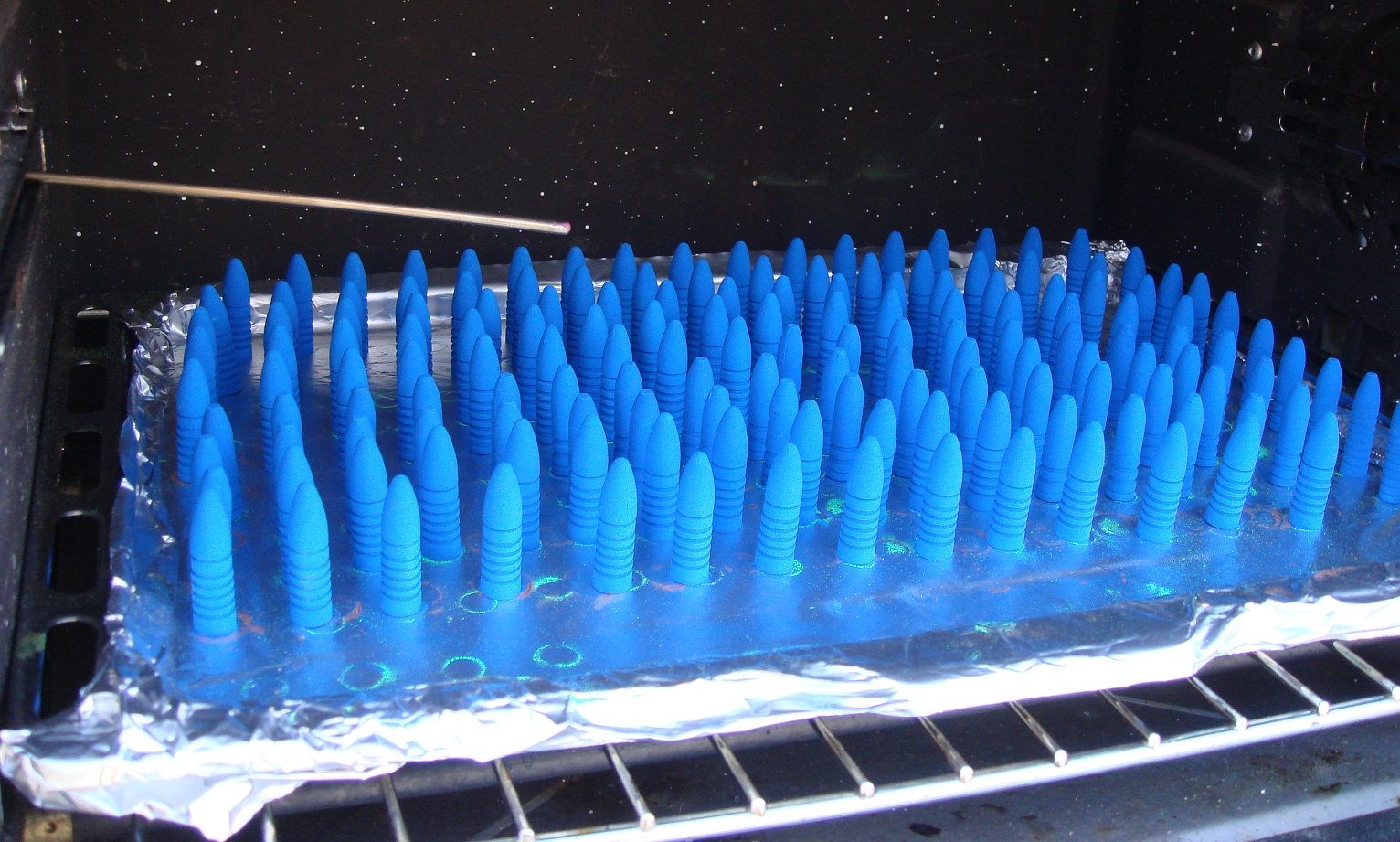

Today, I picked up a new convection toaster oven. To check whether the manufacturer's temp dial was any good, I measured with a TC and found the oven wouldn't get much over 340F at the highest setting. As a result, I set the oven to "always on", plugged in the PID, and measured with the PID TC and a second TC to determine that the PID could actually control the oven at 400F. First batch of bullets, seems like the oven is taking quite a while to get up to temp. Come back 10 minutes later, melted. I moved the rack down but it doesn't seem to make a huge difference.

My question is two-fold: 1) What am I missing here? Is it radiative heat transfer to the TC probe vs. the bullets? That seems like the likely culprit but I am surprised in this temp range. 2) Is the manufacturer's temp dial good enough? What are the implications of PCing at ~350F vs 400F?

Thanks in advance for your help.

|

|

|

Reply With Quote

Reply With Quote