Been working on a project.

.32 rimfire shot shells for .32 rimfire Stevens Favorite.

Made 6 tonight. Went and fired two of them before it got dark.

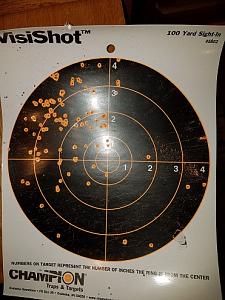

Not a bad pattern from 25 feet. 150 shots per shell. 127 within a 9 inch circle.

Not a donut patter because it is a smooth bore barrel.

Its been fun little project

|

|

|

Reply With Quote

Reply With Quote