Got a new KKM Precision 4.5" 10mm barrel for my G29 for my GSSF match next weekend.

I worked up various loads for it using .400 180 gr. Hornady XTPs and RCBS 180gr cast boolits. Originally had about half a pot of Lyman #2 then added some lead my dad gave me and filled the pot. He did not know the exact hardness of it, but said it should work fine...

Boolits are sized to .401 and coated with Alox before and after sizing.

I also just slugged the barrel and double-checked my boolits. Barrel slugged at .401 and boolits are at .4015... Boolits drop at .403.

Loads are very mild match loads and under 1000 fps, or close to it. Powder used was either WSF or Blue Dot. Fired 65 rounds and was able to get some OK accuracy results, but not what I was looking for. Best group was 2 3/8" at 25yds with a rest. Shot a mix of cast and XTPs but last 10rds were all cast.

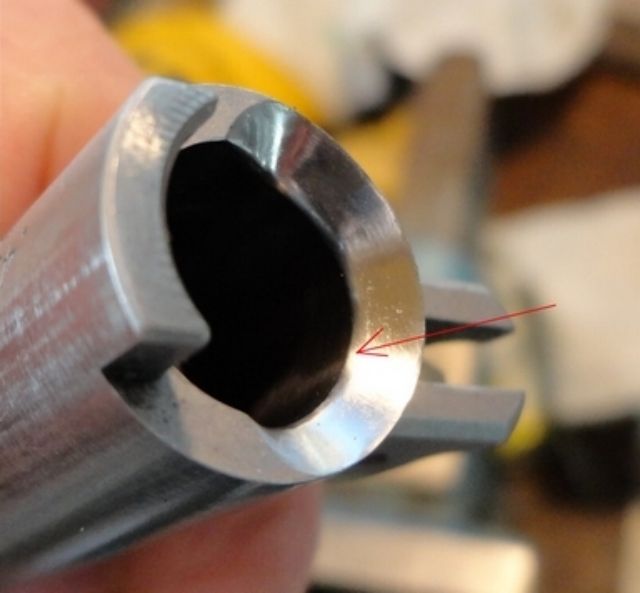

Cleaned the bore with Hoppes and a .40 cal copper wire brush. Then noticed some lead left over and used a .45 cal one and scrubbed for probably five minutes.

It's not coming out.

Guess I will go to the store tomorrow and get something a bit stronger to remove the lead, but wondering why I'm getting issues. Took some pics just to confirm it's leading and not something else...

|

|

|

Reply With Quote

Reply With Quote

DougGuy

DougGuy