I'm jumping the gun a bit, it's not 100% working yet, but it's very exciting to be at 98%.

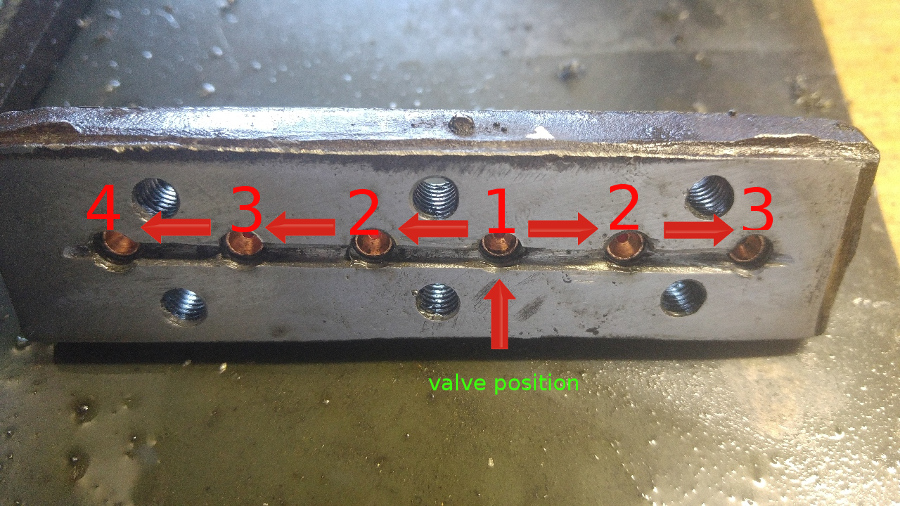

I made a melter with six nozzles to use with the Lee six cavity moulds.

The test pour showed that the front section of the box overhanging the burner frame was much cooler than the melt, so the lead coming through the nozzles was getting rapidly cooled, which made the flow intermittent. I got five out of six nozzles pouring, then things got a bit too cool.

I'm now modifying the melter around the nozzles to have burner gas flow around the nozzles, and under the section of the box overhanging the frame.

Picture slideshow format, will auto-play.

6 nozzle melter for Lee 6-cavity moulds

|

|

|

Reply With Quote

Reply With Quote

Chill Wills

Chill Wills