Among my "other" hobbies is the restoration and preservation of antique engines ...the old big flywheel engine..."hit and miss" style. Most are from 70 to over 100 years and when "found" the majority have been rusted stuck in one way or another...Guys in that hobby have probably tried everything known to mankind to free rusted up bolts, nuts, shafts, stuck pistons, rings, bearings, etc...

We use heat, Kroil, PB blaster, WD-40, and my favorite..Coke (the drinking kind!) An old saying with the old engines and with our old car hobby is that "rust never sleeps". I have a beautiful model 36, 3" square butt Smith that is from the 60's...it's a real nice one except for some minor "flecking" on the frame in one spot...I've gently worked that spot to try and at least hold it as it is but if I'm not on it all the time...it will still show a little minor increase..."rust never sleeps".

I'm old enough with failing eyes, etc that I don't take chances with the better firearms I own...if they need work and I'm at all concerned about my ability or tools..they go to a local smith..

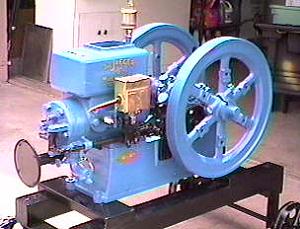

For grins, a couple of pics (before and after) of a 3 hp hit and miss I restored a few years back....nothing turned or moved on this one and it ended up being a terrific runner.

Reply With Quote

Reply With Quote