jmorris,

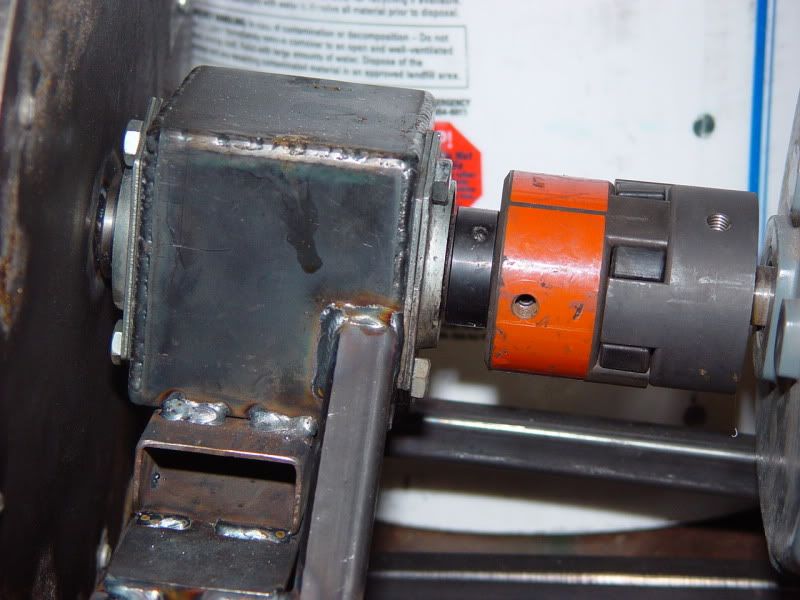

I would like to know the fractional HP of your direct drive tumbler motor. I've shopped ebay and haven't found one yet. Is it speed controlled or just a geared down motor.

I'm afraid I have to copy yours if you don't mind. Its straightforward and elegant in its simplicity. The money saved on bearings and rollers can be put into a decent motor and I'd rather go that route.

Thanks,

Joe

|

|

|

Reply With Quote

Reply With Quote