The rifle is a Pedersoli 1885 High Wall in 38-55. The twist is 1:12. I'm using Starline 2.125" brass, new and trimmed to 2.125 - 2.126. Really pleased how the trimming came out. I slugged the bore all the way through, the first 6 inches from the chamber and the last 6 inches at the muzzle. The measurements for all three sluggings came out the same. Bore = 0.372"; Groove = 0.379". The goove was dead on, the bore could be +0.0005" so I'm not going to worry about it.

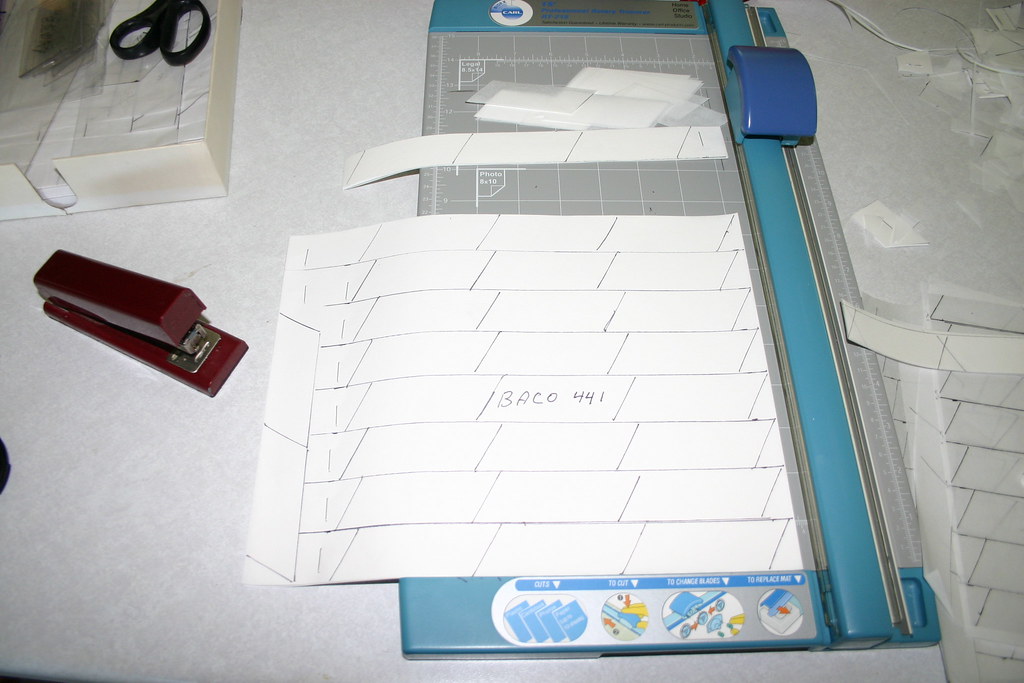

To start I want to patch to bore diameter, or close. I test wrapped 10 different papers and settled on A) BACO 9# Onion Skin wrapped 3 times (0.3733"). Down the line I'll probably try B) Aquabee Layout Bond, 2 wraps (0.3754") and C) Staples Notebook paper, 2 wraps (0.3741") as they were close.

The bullets are the BACO 0.365", 300 grain pure lead slicks. Actual measurements were 0.364" and 299.5 to 300.8 grains. The average length of 10 was 1.16875". Very nice looking bullets.

I had to mess and fiddle with getting the paper the right length so it didn't overlap. I thought I had it and wrapped 10 bullets, leaving them to dry over night. Next morning I found that 7 were actually overlapping edges so I took them apart and started over. Took me a couple of tries before I figured out that the paper was still stretching as I rolled them bullets. After learning that lesson I watched carefully and stopped before getting an overlap. I dried these 7 in the oven and they look great. I took the micrometer to all 10 and found the 3 that dried overnight were 0.3729" (yea, all 3). The 7 oven dried ranged from 0.3731" to 0.3734". This is amazing because it isn't me - I'm a bumbling fool with 11 thumbs.

Next is working on the load. But I wanted to share the bullets. I've enjoyed and learned from this forum and wanted to share. Comments welcomed.

|

|

|

Reply With Quote

Reply With Quote