OK I am running a thread to pick everyones brain about some possible upgrades I am currently experimenting with on the Lee pro auto disk powder measure, the one's with the Red round hopper.

These are nothing more at this time than thoughts and tinkering on a few measures I own, but may consider something else in the future.

Meanwhile here's a list of what I am playing with at the moment:

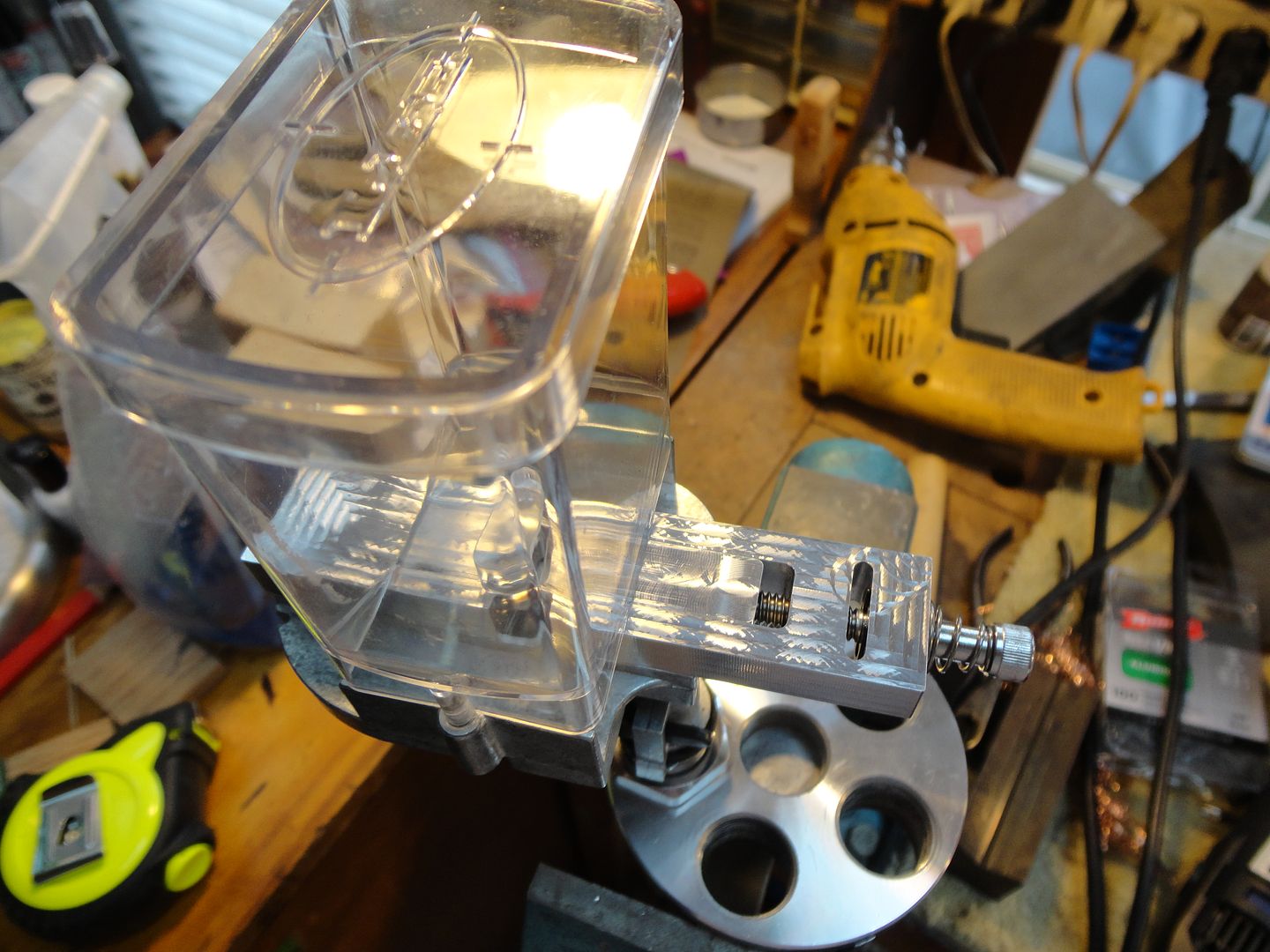

A larger hopper, up to 2 pounds

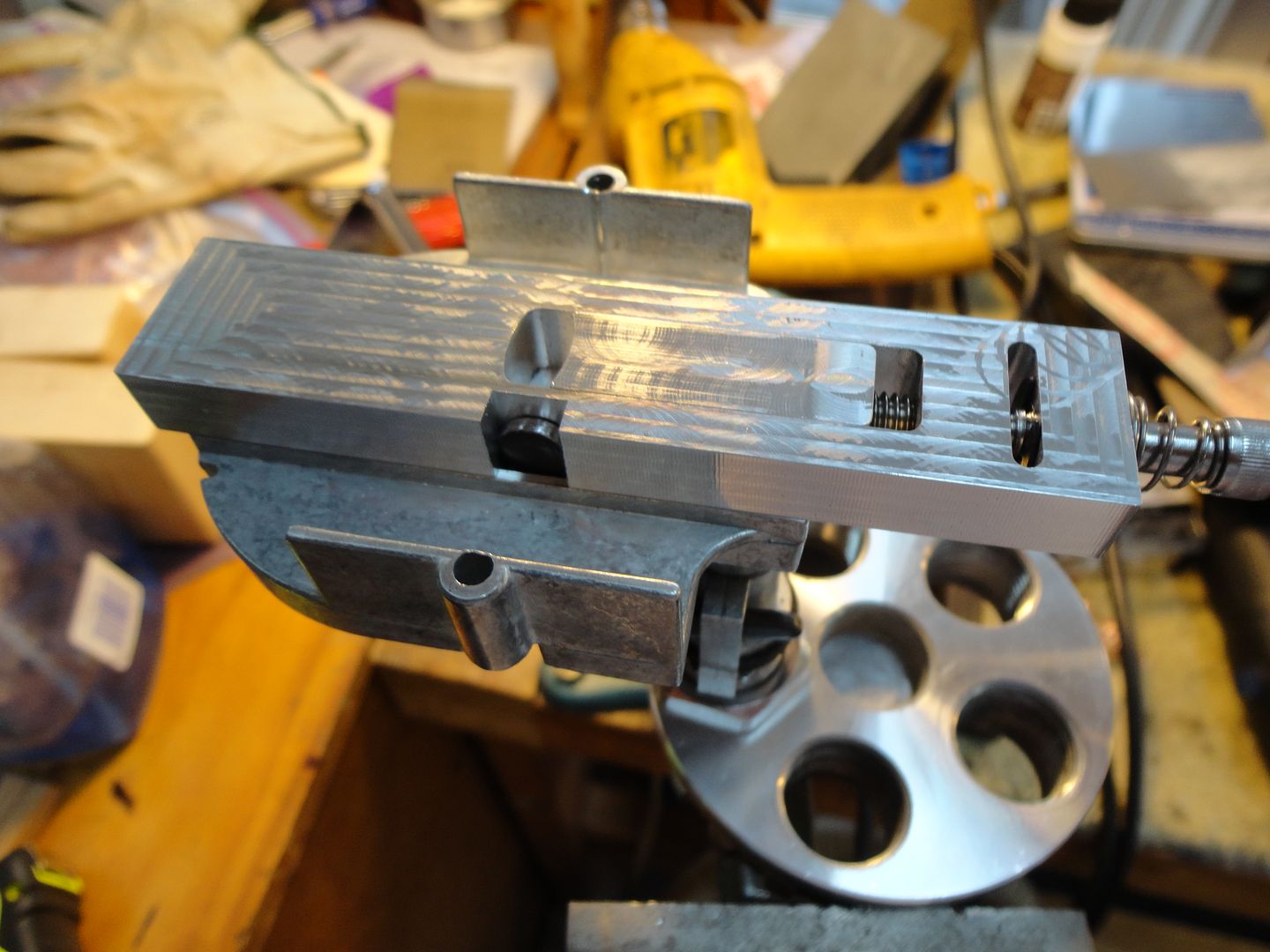

a powder cop for both standard and larger powder hoppers, I know Dillon has one I hope I can do better, we'll see.

stopping the leaking issues with ball type powders

keeping the powder measure from "sticking" and not dropping a powder charge, doing a lot with that right now!

Other Ideas may pop up as I continue "tinkering"!

Currently I have a test bed measure set up to drop 40 Grains WW748 for my go to 308 load, testing will be running the measure on a Classic Cast press so I can weigh each charge and examine any leakage that occurs as it occurs.

If all goes well I will be setting up a Pro 1000 press to load 308's in the near future to make sure the vibrations of the progressive press don't fix the adjustments of the modified powder measure.

Question: is anybody else interested in these ideas?? If so please feel free to post your comments with the understanding that I will not be doing anything commercial anytime soon if ever!

HM

|

|

|

Reply With Quote

Reply With Quote

DougGuy

DougGuy