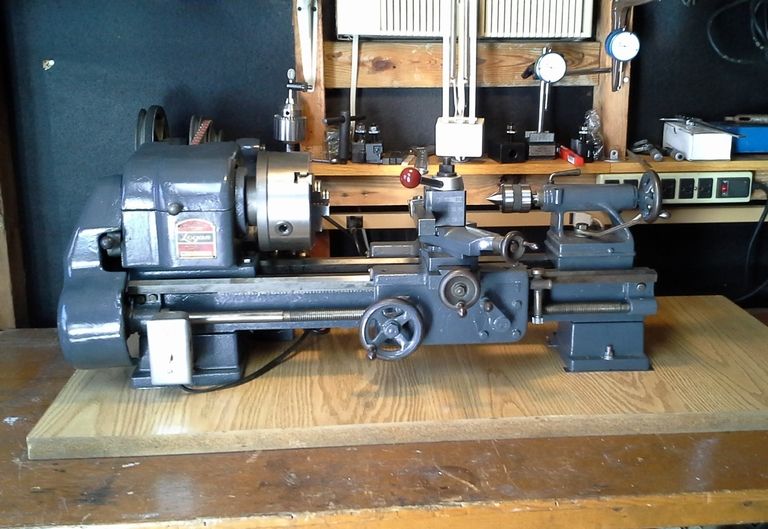

We had a garage sale around here this past weekend and stumbled across a 1945 9 inch southbend metal lathe. Here is a picture.

It comes with the tooling and bench. I got a basic lesson today. I gave 1100 for it. Seemed reasonable to me. I have not run a lathe in 40 years and have no idea what they are going for now. The industrial lathe my dad had didnt cost near this price.

Now, I could use some ideas where to start learning. Consider me having zero knowledge and go from there.

Thanks to everyone in advance.

Mike

|

|

|

Reply With Quote

Reply With Quote

DougGuy

DougGuy