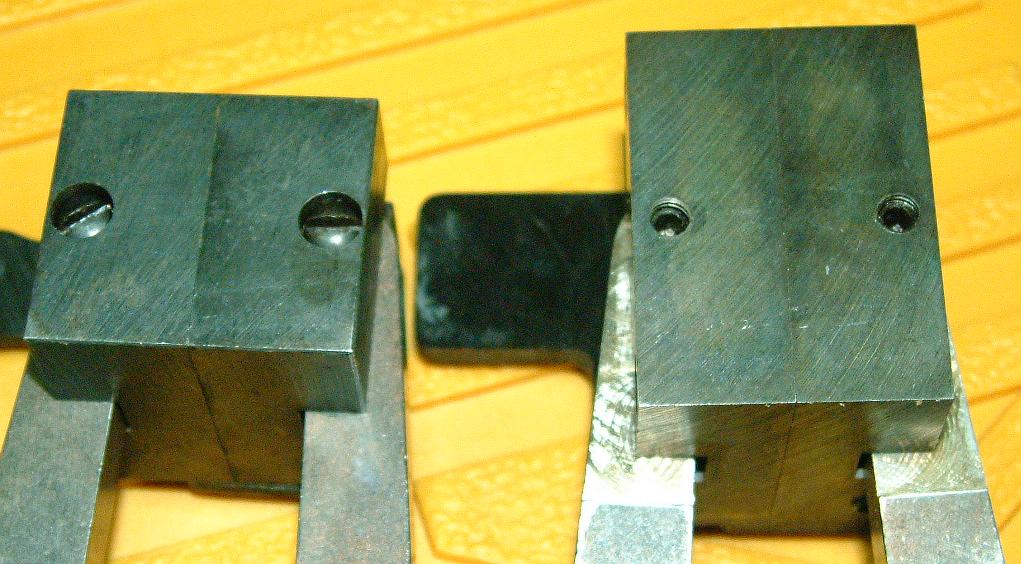

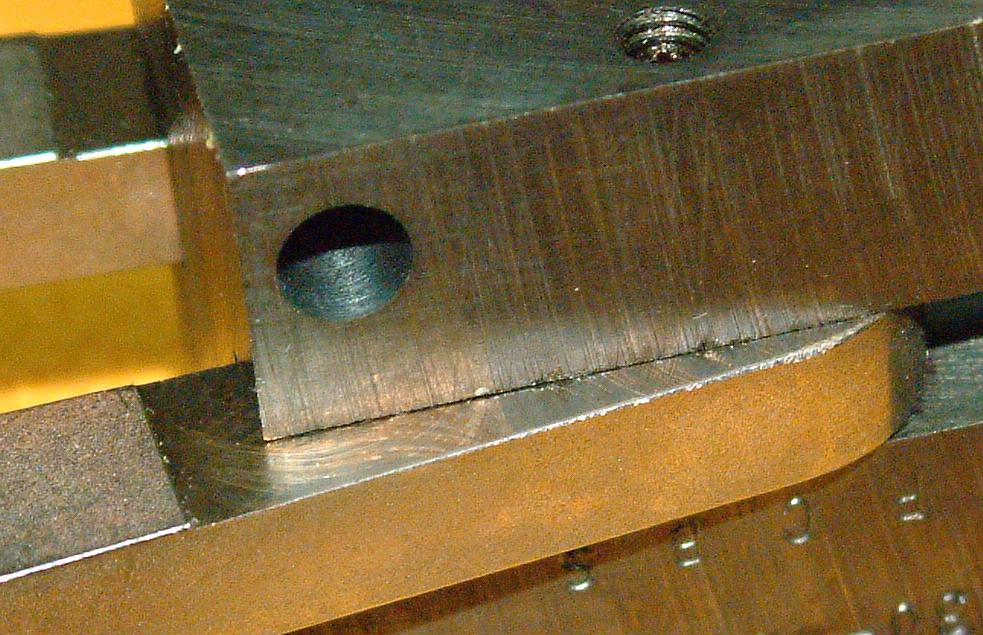

Well i broke my spare mold handle. Damm Lyman break handle by the screw in the mold. Is their way to weld them back up. Like to braze them or mig weld them. They are not cheap to replace $$$$$ either. Or are their other handle can be used instead of Lyman that are cheaper and a better design then Lyman weak spot where they break.

|

|

|

Reply With Quote

Reply With Quote