last year I made a few modifications to my Ruger single seven. www.rugerforum.com/phpBB3/viewtopic.php?f=3&t=223644

one of the things I did to it was to file down the stock aluminum front sight to resemble the front sight on Elmer Keith's No.5. since it was aluminum the only way I could re-finish it was to paint it black which with use would flake and look pretty cruddy.

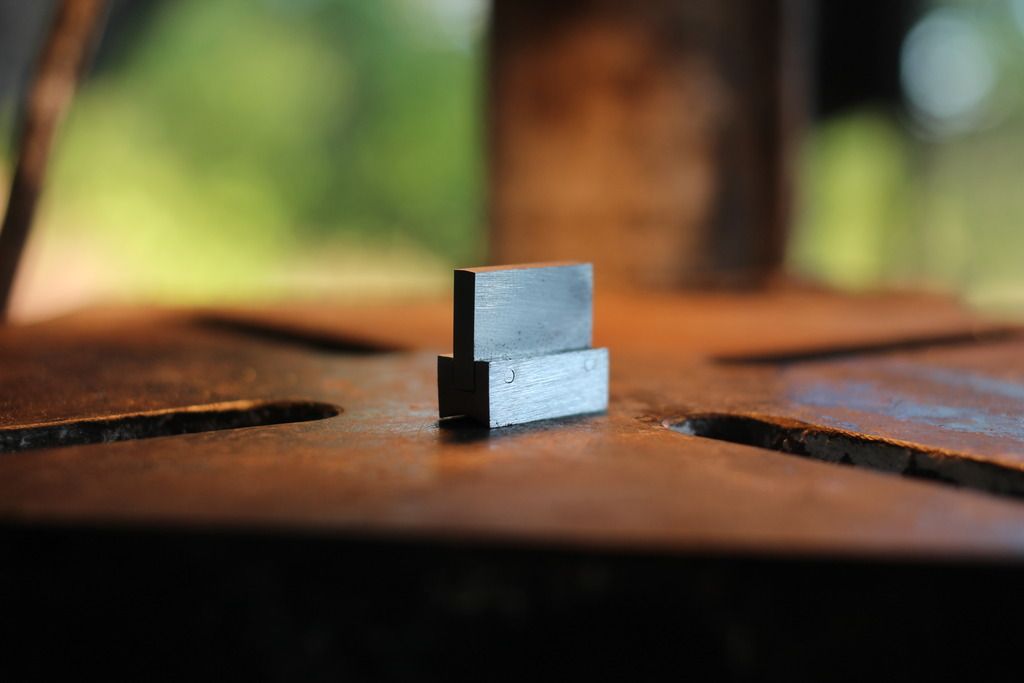

so a few months back I got to thinking it would be really cool if could use a pinned in base on the gun so I could change blades whenever I wanted to. well one thing led to another and before long I wound up starting on a Colt flat top target style Base with a Keith style sight blade. rather than solder it on it would utilize a screw just like a regular single six front sight.

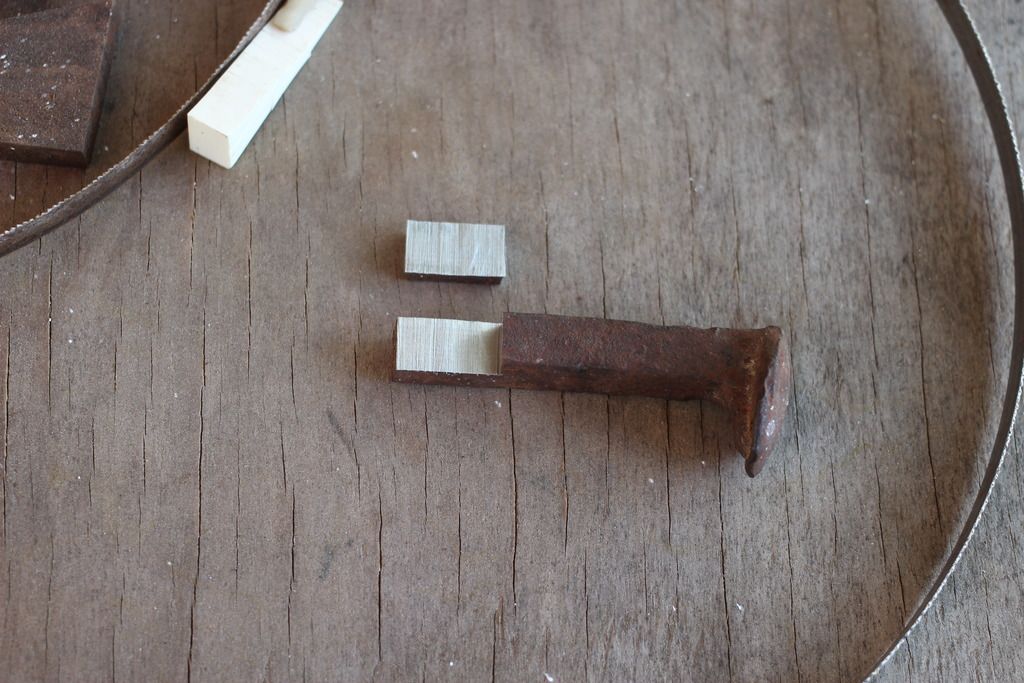

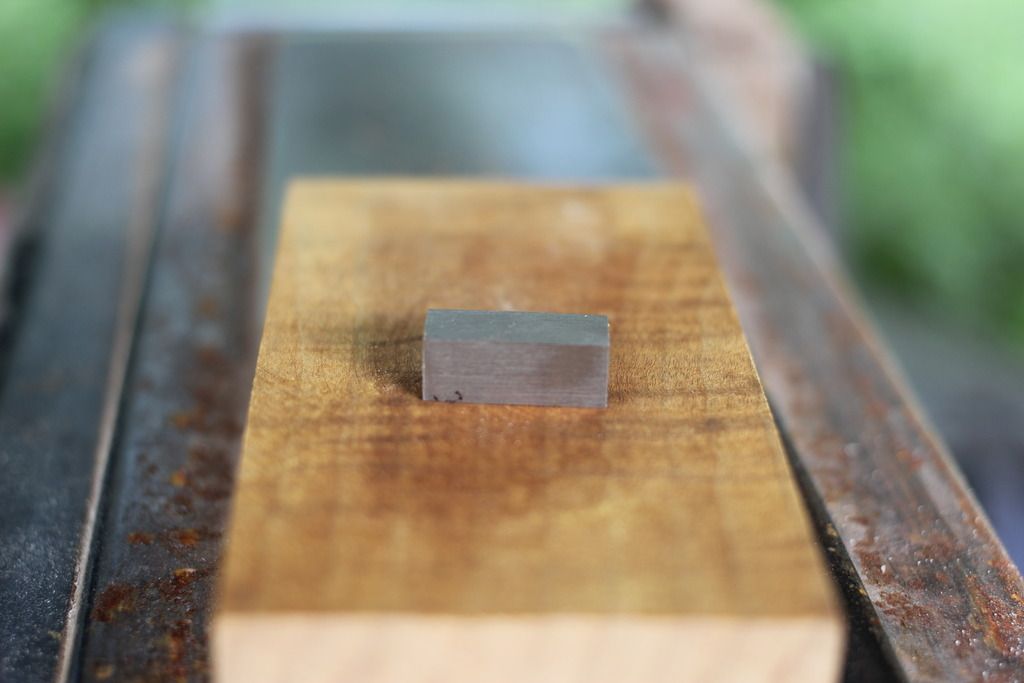

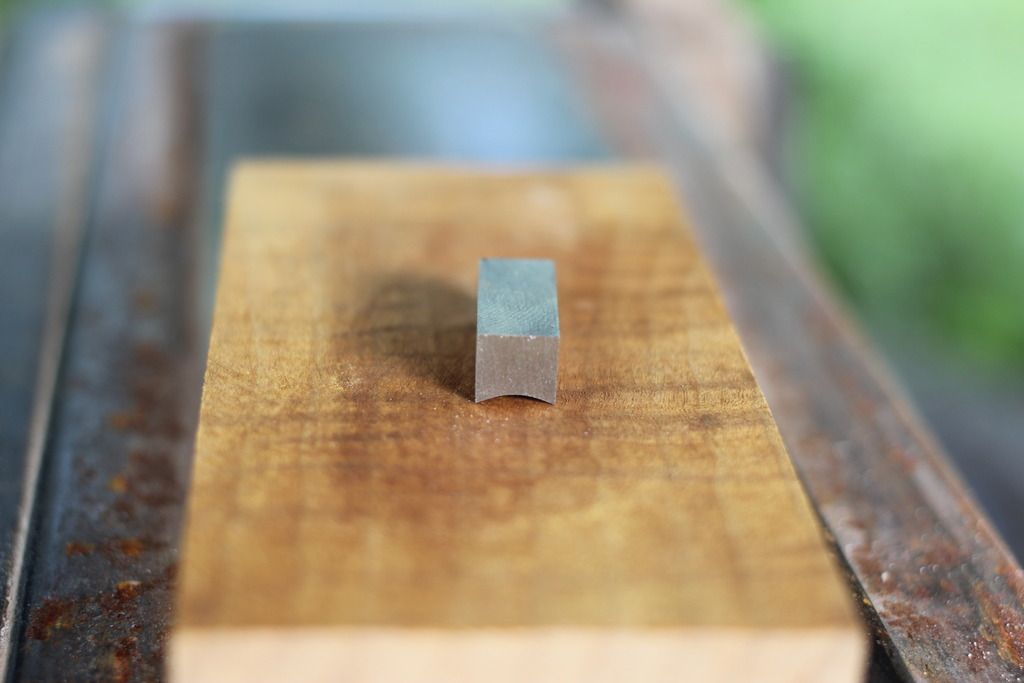

starting out I decided I wanted to do as much as I could with the materials I had on hand. after looking through my steel pile I settled on a railroad spike for the sight base. after cutting off a piece and squaring it up on the belt sander I used a dremal sanding drum to start cutting the channel for the barrel. once I had it roughed out I wrapped various grits of sandpaper around the barrel and continued sanding till the base sat on the barrel pretty well.

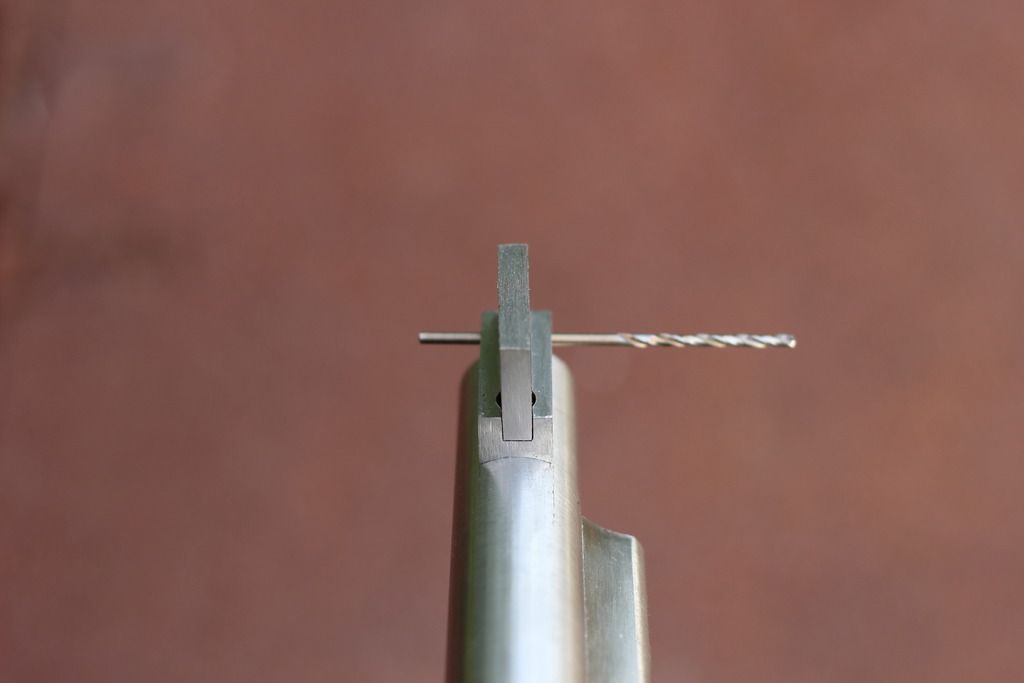

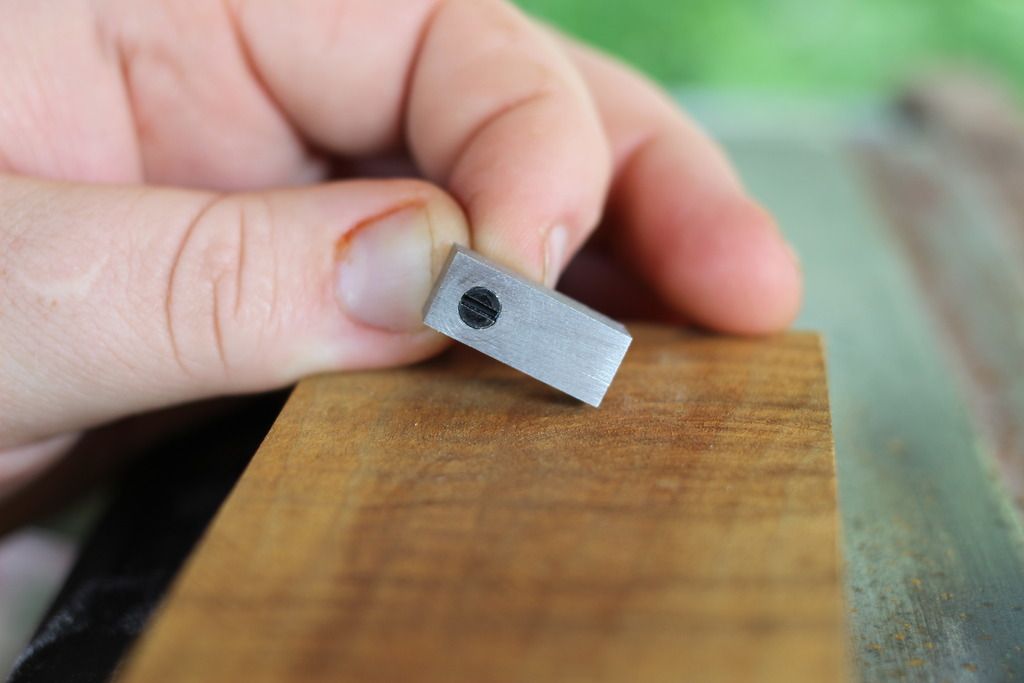

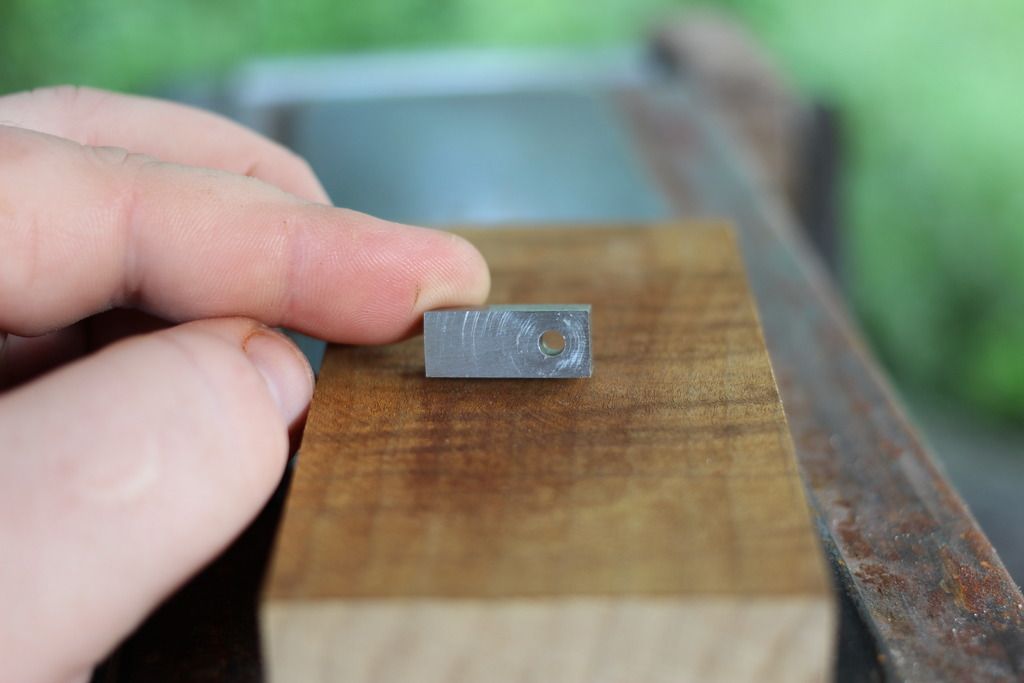

next I drilled the screw hole. starting with 9/64" for the screw body and then 3/16" for the screw head.

while that measurement was perfect for the stock Ruger screw, the head of the screw I got to use for this project ended up being slightly bigger. to fix this problem I chucked the screw up in the drill press, turned it on and used a file and fine grit sandpaper to take off some of the screw head diameter.

|

|

|

Reply With Quote

Reply With Quote