We were discussing this gun http://castboolits.gunloads.com/show...KA-WR-500-450) and it's unusual chamber dimensions, lack of any military markings or serial number, extraordinarily fine condition, and theorizing on the possibility that it was a tool-room special, maybe for an experimental cartridge development. It's basically close to the WR #2 Musket (11.43 x 60R Romanian), but with a body that's .050" smaller than standard. Indeed, the only marking on the barrel breech under the forend besides the house proof mark is " - 05 " (for -.050" ??? ). No markings except the Steyr logo and date on the left side of the receiver. Unmarked anywhere else on the receiver. If the gun was not unfired, its condition gives a mighty good impersonation of that status!

Anyhow, after much study, the closest thing I could come up with for parent brass was a box of .43 Basic Brass from Stevi Machine that I had on the shelf for maybe 30 years. Rims run about .082" thick, body about .518", and plenty of length. After searching through a bunch of oddball dies, I found that a C-H .44-95 Peabody-Martini die would form a shoulder and neck just a bit undersize. I trimmed to 2.375" with a C-H power trimmer based on the chamber cast, allowing for about .250" freebore before the very short leade and Henry rifling. The case neck is just thin enough to allow a bore diameter (.449"-.450") bullet to seat in the chamber, so I used some paper patched 450 gr .441" swaged pure lead hollow base bullets from Buffalo Arms. Patched with 9# onion skin they run about .448"-.449" and are basically a press-fit in the bore. I expanded the first half inch of the necks with a .450" expander so I could seat the PP bullets without marring.

I used Federal Magnum 215 primers, and 78gr bulk Swiss 1.5F topped with a lubed felt wad. Pressed the bullets on top of the wad and then seated to uniform depth with a .44-77 die that fit the bullet nose. Chamber neck is quite tight even with a bore diameter bullet, so I used the .44-95 P-M sizing die to squeeze the neck of the loaded cartridge just enough to allow it to chamber (basically removing the small amount of expanding that I did to seat the bullets.

I set up an N-SSA 100 yd match target (8" black bull for scale) at 100 yd. Shooting off the bench with 10 rounds.

The warrior that never went to war.

The only markings at all on the receiver of this gun.

Note Romanian-style rear sight with ladder extgension

Getting ready...

THIS puts the cartridge more to scale.

Chambered (but unfired and extracted) round alongside a fired case. Note case formed in die has a bit sharper shoulder.

I set the die so the case would headspace on the shoulder in case rim thickness was inadequate, getting a slight interference fit upon closing the breech.

I won't size at all from now on due to the chamber dimensions.

Fired cases chamber and extract beautifully, with what I'd call a "brush-fit" upon closing the breech.

Also note that at this seating depth, the patched bullet lightly bears on the lands for approximately 1/4", wiping off a bit of powder fouling from the throat.

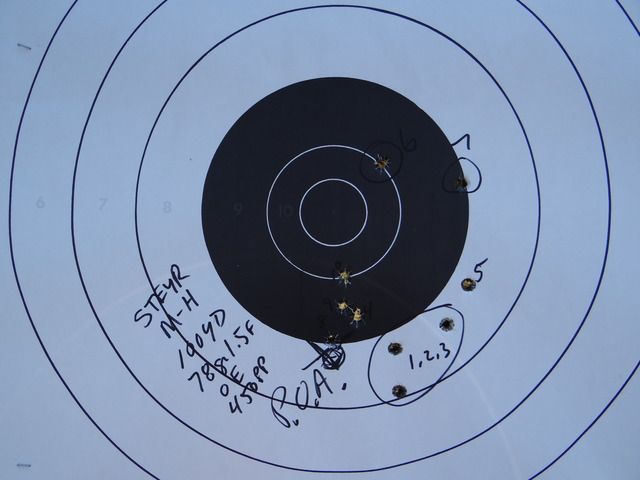

Here's the target. Point of aim is 6 o'clock on the black. First three fired with blow tube between shots, without checking target. I started checking the target after the first three, and was noticing a bit of vertical stringing with continued blow-tube-only use, so after shot 7, I wiped with 3 spit patches, then continued to shoot the remaining three shots. I had also realized after shot 6 that the butt plate was on my shoulder joint, rather than in the "pocket", so I adjusted my hold. That pretty much moved the shots to the center of the target (left/right), with the last four going into a roughly 2" group. I bet with further load development I could shrink that, but that's a pretty pleasing result for a first outing with an unknown cartridge, cobbled ammunition, and essentially a full military load.

It shot well enough, and fired cases look good enough, that I ran back in the house and formed and trimmed the other 10 cases from the box so I'll have 20 to mess with.

Now I've got a bunch of bullets to paper patch...

|

|

|

Reply With Quote

Reply With Quote