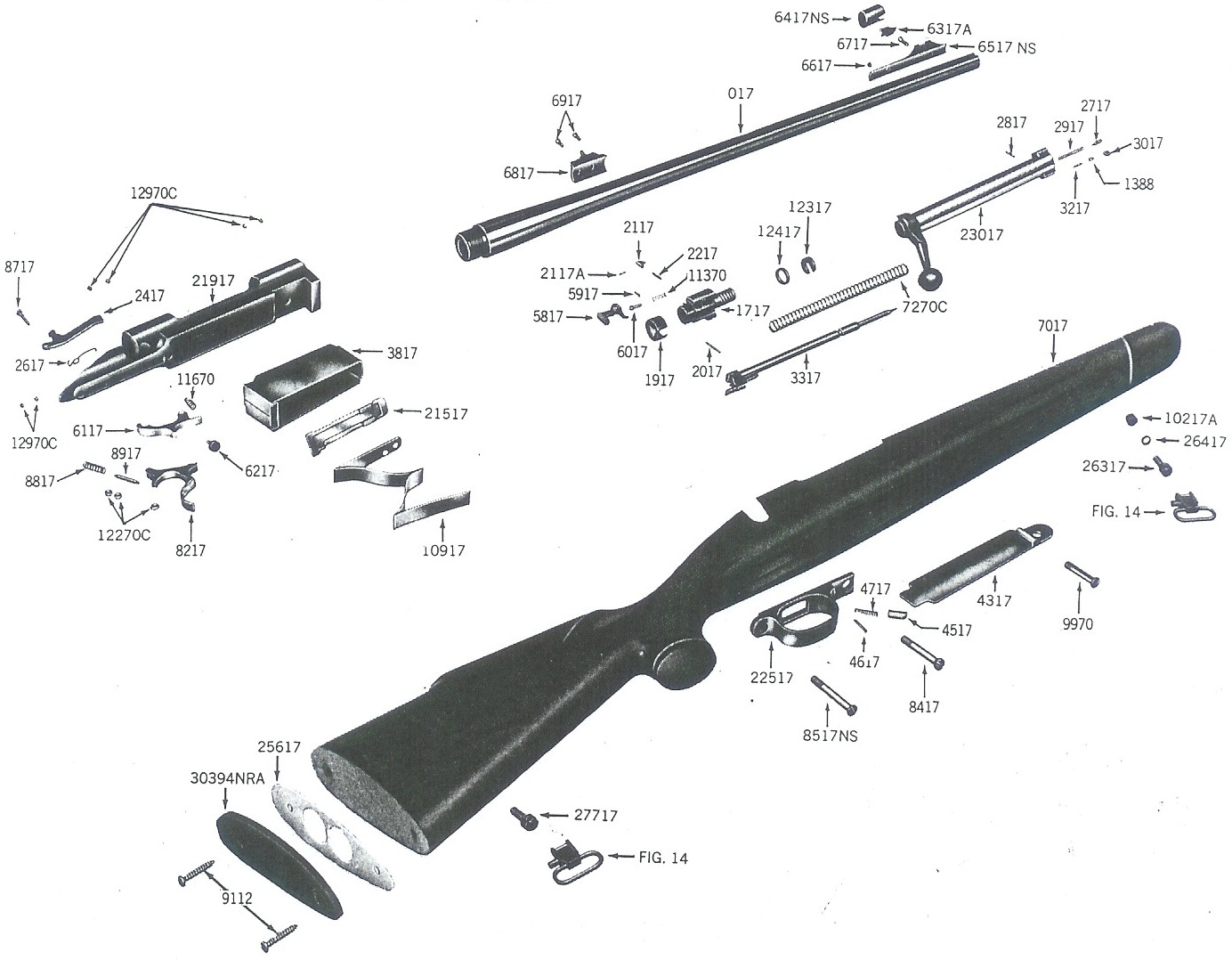

So my Searschester is simply a cheap post 64 Model 70 and share the same low budget extractor . . .

Hence the problem.

Got it out last fall to test loads (RD's 165 boolist outa that gun) and after the first shot the bolt came back and case still in the chamber.

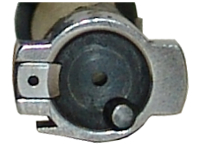

Come to find out whatever is behind that low class excuse for a real extractor that wiggles, plunges pushes of pulls does none of those things and so the extractor just flops loosely.

I have had KROIL and penetrating oil soaking it since and still stuck today when I tried it.

However it is made it is far enough forward that the extractor won't come out, but can not be pushed back.

Any ideas out there on "UNSTICKING it?

Issues like this is why Mauser made real extractors on the original.

|

|

|

Reply With Quote

Reply With Quote