As the topic says, i'm going to have a shot and building a casting machine based on a master caster. I have a MC that is automated, i want to have a go at building two friends for it. I picked up the main parts to do the build, i just need to work out how to put them together.

To go with the casting machine(s) i want to build a sizer, i have a motor to drive it and the start of the design in my head. The only limiting factor to all of this is time. It's going to take a while, but with a bit of luck i'll get there.

As there are a few members here that like to make their own gear, i figured some may be interested in this project. Either it will work, or fail miserably

So far this is what i have on hand to start:

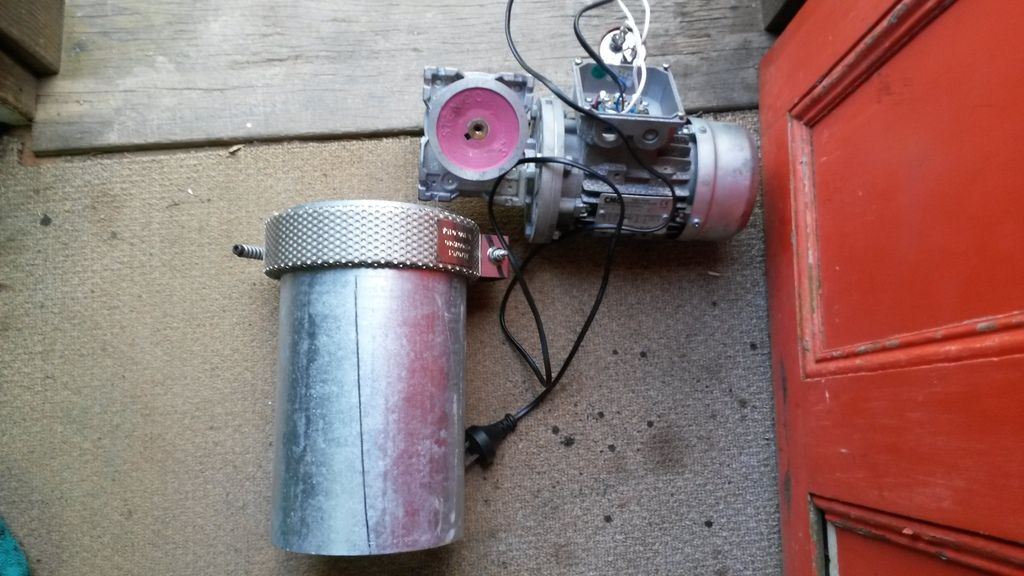

Heating bands for the pot:

Electric motor for the sizer and a piece of pipe to make two pots with. Just the right size for one of the heating bands:

Cylinders, a few valves (need more but i have time till they are needed) and air regulators:

|

|

|

Reply With Quote

Reply With Quote