Now I have a little experience loading and shooting 45-70 black powder paper patched cartridges in my dp 1874. Thanks to you all that gave me tips when I didn't know where to start, especially Charlie Montana who was kind enough to write me some thoughtful and detailed PMs to get me started.

I'm feeling good about making cartridges- at least I have a starting point so I can fix mistakes and try stuff. I am using a taper crimp die to hold the bullet so that it spins easily but doesn't fall out of the case. I decided to just use an over powder wad cut from a milk carton and rely on 1 damp/2 dry patches for fouling control. I'm using 70gn ff goex (almost a full starline case) compressed so that 3/16" of bullet fits in on top. I have paper that adds .012 wet wrapped that worked great for groove sized smokeless loads so I bought a baco .438 money bullet mold that makes nice smooth slugs. I think it was a mistake to not ask Charlie if such a small diameter was a good idea before buying it since he was helping me get started, but I am trying to make it work.

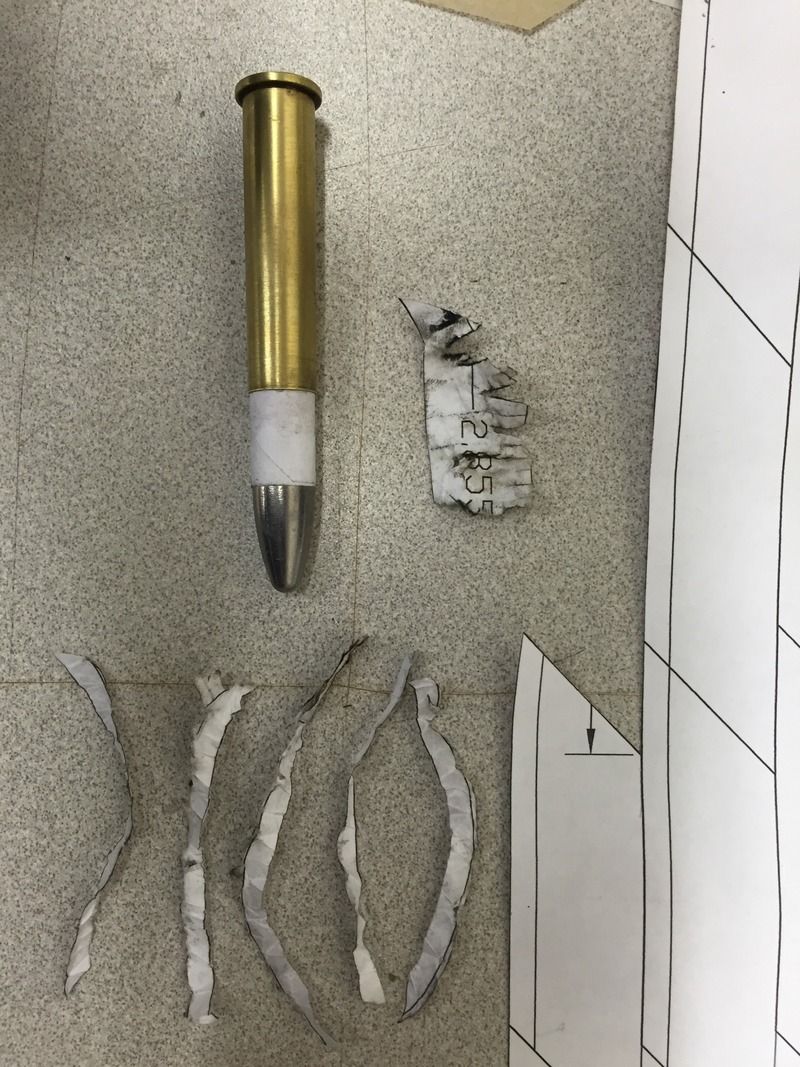

My first time out I tried it with a thinner paper wrapped to .4465 in my .450 bore. I figured it might allow follow up shots but all I got was tumbling bullets and many perfectly sideways bullet holes at fifty yards in a shotgun pattern. My next outing was with the thicker paper- the final package was at or just over .450 and took a firm push to chamber but wasn't difficult. I had high hopes! This load sucked too but at least 9/10 made round holes and not bullet profiles! Accuracy was bad. I was excited to see some 'confetti' for the first time (hard to find in snow on earlier range trips) but after I went and got it I found it was all strips cut clean around the base of the bullets! I was using the template from the stickys here so there is a line printed on the patches right where the base's corner rolls on. Here's a pic of the template, a cartridge, and all my confetti. I was getting slivers of lead on my cleaning patches too. I only found the one patch from the shank. I wonder if the way it's sliced toward the back tells me that the bullet is slugging but in a tapered way fatter at the base.

I have three things in mind to try next.

#1: I ordered some 45-90 brass to trim for my chamber. I wonder if this would fix a lot of my problems? The 'rings' of paper cut by shooting this load seem to be saying that the bullet is slugging up into my extra case space and freebore then getting cut by the leade? I'm going to put up another post (short & sweet to hopefully get concise responses) concerning this process.

#2:If filling my chamber better with brass doesn't get me 3-4 moa as a starting place for more detailed load tweaking I would strongly consider either trying some swaged or cast bullets or even just buying a mold that can use thinner onion skin paper to get to .450". Around .444 to .446ish depending on my choice of paper. Hopefully this would slug up better and allow the rifling to cut the paper more reliably. I only found one piece of confetti from the bullet shank so it is possible that the bullets are wearing streamers, especially if only the base is fattening and the wraps aren't cutting thru.

#3:A member here was kind enough to offer the use of his custom reamer for the cost of postage. It cuts a nice taper leade up to .459 then stays there as deep as you wanna spin it in. This seems like an awesome way to cleanly chamber a .458 package seated out as far as you wanna cut. Right now my chamber will hold a Lee 500gn bullet sized down to 452 then patched back up to 458 seated pretty deeply into the case- just a hint of patch shows. I know it would work great with smokeless patched to groove but with smokeless I wouldn't need as much powder capacity so then I'd be messing with dacron. Also I only really want to shoot BP in my 1874 pedersoli sharps. I already shoot grease groove smokeless in my 1895 marlin. I know most people shoot bore size with BP and have read pages and pages here and on bpcr forum. It would be neat to have a custom rifle and my gun does shoot factory jacketed ammo around 2.5moa so I figure it does what it's designed to. It would be a shame to whittle on an expensive gun if I don't have to. I know that the long taper 'paper patch chamber' vs the abrupt sammi chamber used to duplicate the bullet's experience is a muzzle loader is somewhat of a hot debate.

If you read this far I really appreciate it and I would love to hear any opinions on my load development experiments and options. My goal is to ring a 4" gong at 200 yards. Unfortunately I don't have long range or silhouette options near home. There are no 1000 yard comps in my future. I think my goals are pretty modest.

Thanks

Radar in Bucks county

|

|

|

Reply With Quote

Reply With Quote