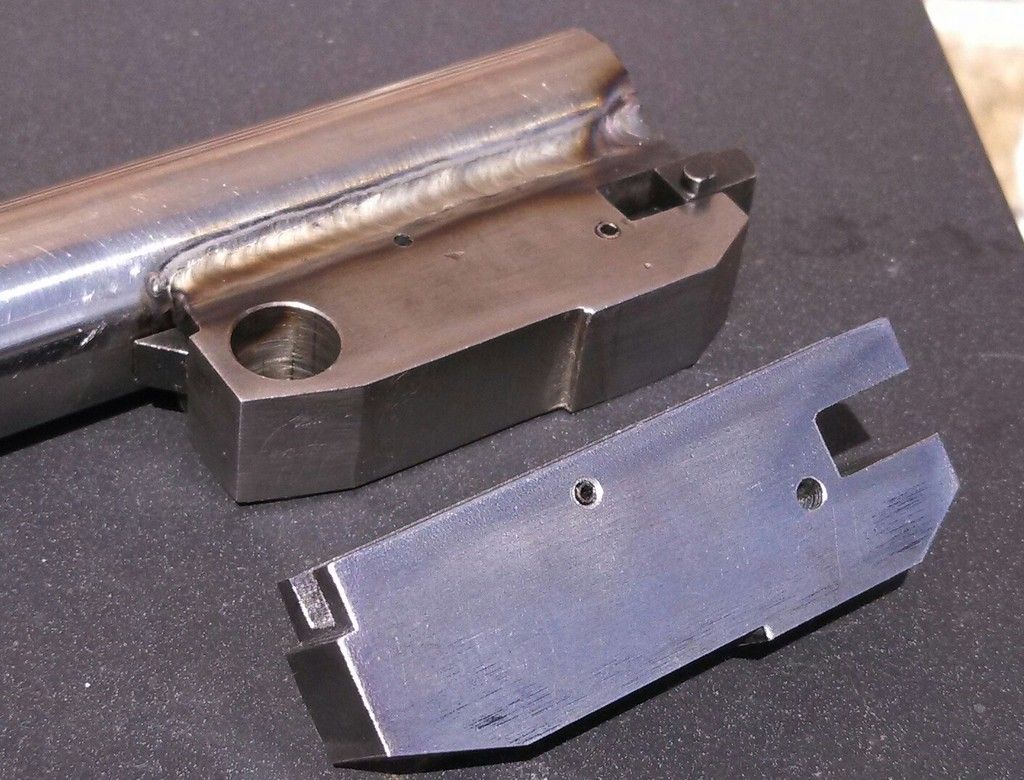

Does anyone have prints of the bottom lug for a contender barrel. I have two different barrels and of course they are not exactly the same.

I am sure I could just make one in the middle of what I have and be OK as both work but would be interested in knowing what they are supposed to be and what tolerance they made them to.

|

|

|

Reply With Quote

Reply With Quote