So my neighbor gave me a Lowe’s gift certificate for plowing his driveway last winter when his nephew was house sitting while he and his wife wintered in Hawaii. I told him it was not necessary, that’s what neighbors do, but he insisted.

I picked up a Dremel model 4000 and the quick-release accessory blade kit with the gift certificate.

Last year I bought a mini chop saw off of eBay with the specialty fixture to cut down resized 223 cases to 221 Fireball or 300 Whisper. Da@% saw broke after the first use.

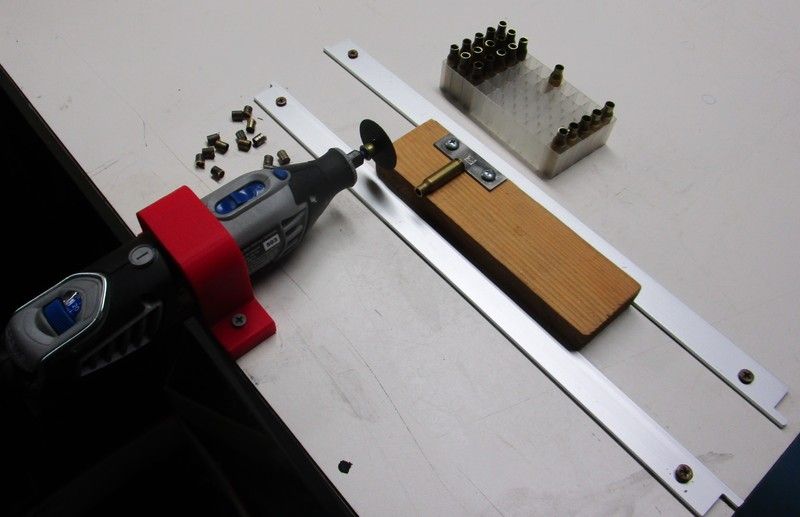

I found the red Dremel holder on eBay and thought I might make my own brass cutter.

The setup doesn’t look like much but it works really, really well. I used file folder carriers from an old file cabinet as the guide rails and a 1”x3” piece of scrap wood as the slider. Using the Dremel I eyeball cut a recess into the wood. It nests the case perfectly and is tightly secured by light finger pressure. The small piece of metal on the back end of the case acts as a stop so I get the exact same length cut on every case. From there it was just a matter of screwing the guide rails to the table. Very simple. I will likely mount the whole assembly on a piece of hard maple shelving I have for easy storage.

Getting the reforms cut to length was the biggest problem converting 223 Rem to 221 Fireball. I tried a mini tubing cutter and the mini chop saw before I arrived at this solution.

I wish I had never purchased the el cheapo mini chop saw but that was an integral part of the “system”.

I really like this Dremel.

|

|

|

Reply With Quote

Reply With Quote