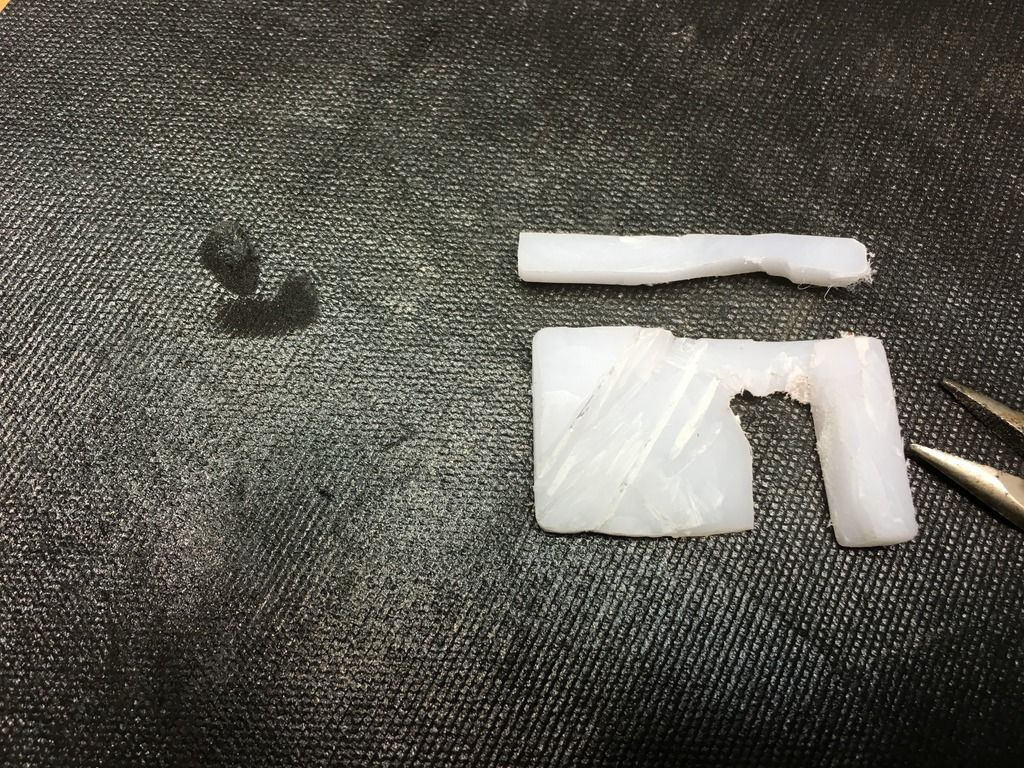

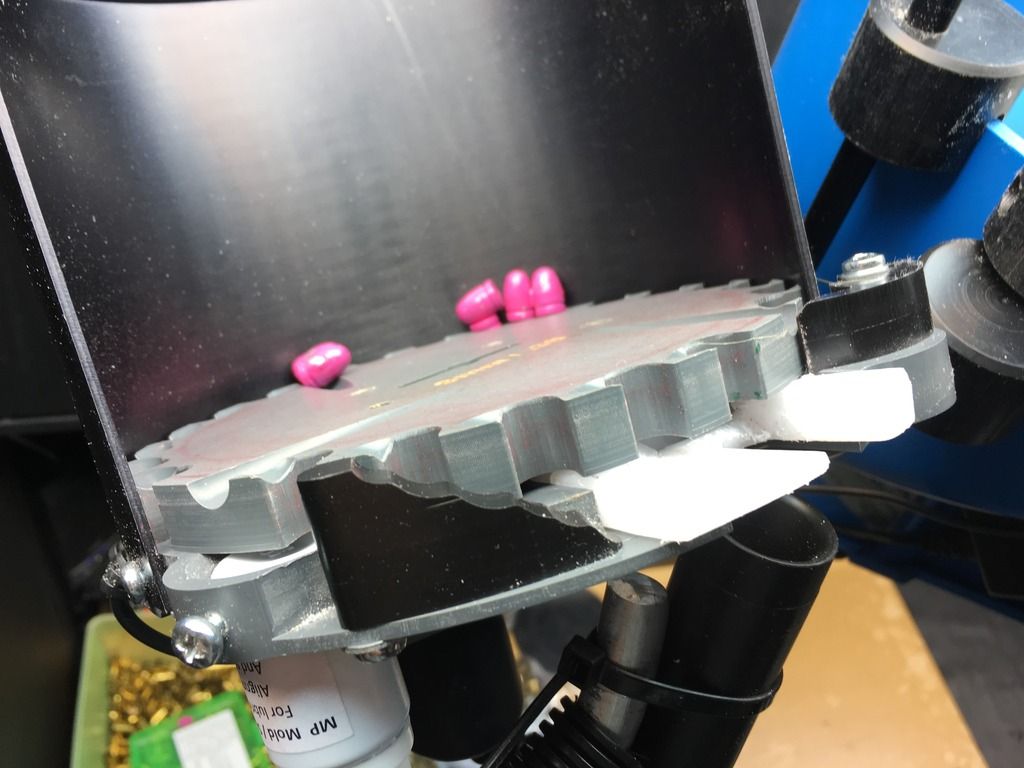

I thought some of you might be interested in a solution I came up with to accomplish this. I used a piece of cutting board and dremeled it out. It works basically flawless if the powder coating of the bullets is nice and uniform. I sometimes have a problem of excess powder coating from the bullets sticking together and making a little bur when pulled apart. This usually only gets caught up in the stargazer feeder tube and not the mr. bulletfeeder. If someone could do this with a 3d printer it would be much nicer!!!. Anyways its proof of concept and plan to use it till Mr. bulletfeeder comes out with the official nose down adapter. Please let me know if you have any questions.

https://youtu.be/tRHdEzsmwGc

John

|

|

|

Reply With Quote

Reply With Quote