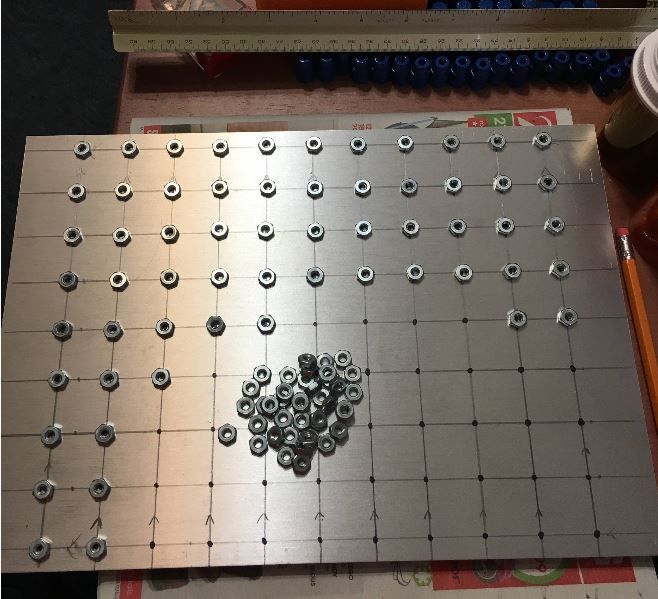

I bought two pieces of aluminum (3/8"x9"x12.5") to make two nice thick trays. I was tired of having different sized trays and using the flimsy aluminum cookie trays that came with the toaster oven. These are nice and thick. I find that heavier is better because it dampens any fast motions while moving the tray of sprayed boolits. I'm starting out with a 1" grid on this one, so I can do the 45 boolits with plenty of room between them (to avoid "shadows"). I'm going to cover this tray nice and tight with regular foil to hold the 8-32 nuts in place, then I can put non-stick over the top for spraying. (I prefer 6-32 nuts, but HD was out of them.) Then I can just replace the top sheet without disturbing the nuts. I have done this before and I can usually spray a dozen times before I get careless and disturb the pattern when changing the "dirty" sheet. By then I'll know if this spacing is perfect for me and I'll JB-Weld the nuts to the tray, but I wanted to test out the spacing for a bit before I commit.So I'm building two of these 99-count trays for rotating out and provide fairly continuous action at the spraying table.

|

|

|

Reply With Quote

Reply With Quote