I might go ahead and flame-harden that small section of the Threaded-Barrel-Stub; at least the very face of it. I'll just have to wait and see. I don't want to go from perfectly-fine as it is, to brittle and prone to breaking off down the road.

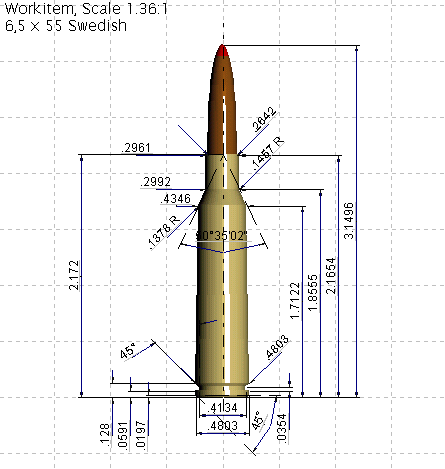

I got a chance to measure the inside front-to-back length of my K31 magazine. It measures 3.130" or there abouts so I guess this would be the max length we could make our reloads.

HollowPoint

|

|

|

Reply With Quote

Reply With Quote