I am using a lee push through sizing set for .358 on boolits cast in a new lee .358-150 mold the boolits are dropping at .3594 155 gr. with ww lead. When I push them through the sizer I am getting a small lip on the base of the boolit. I have read that using a top punch will stop the boolit from having a lip. I have checked for a top punch for the lee kits with no luck. RCBS & Lyman top punches are to short to reach the sizing ring in the die.

Does anyone know of a person or company that sells a top punch for the lee dies?

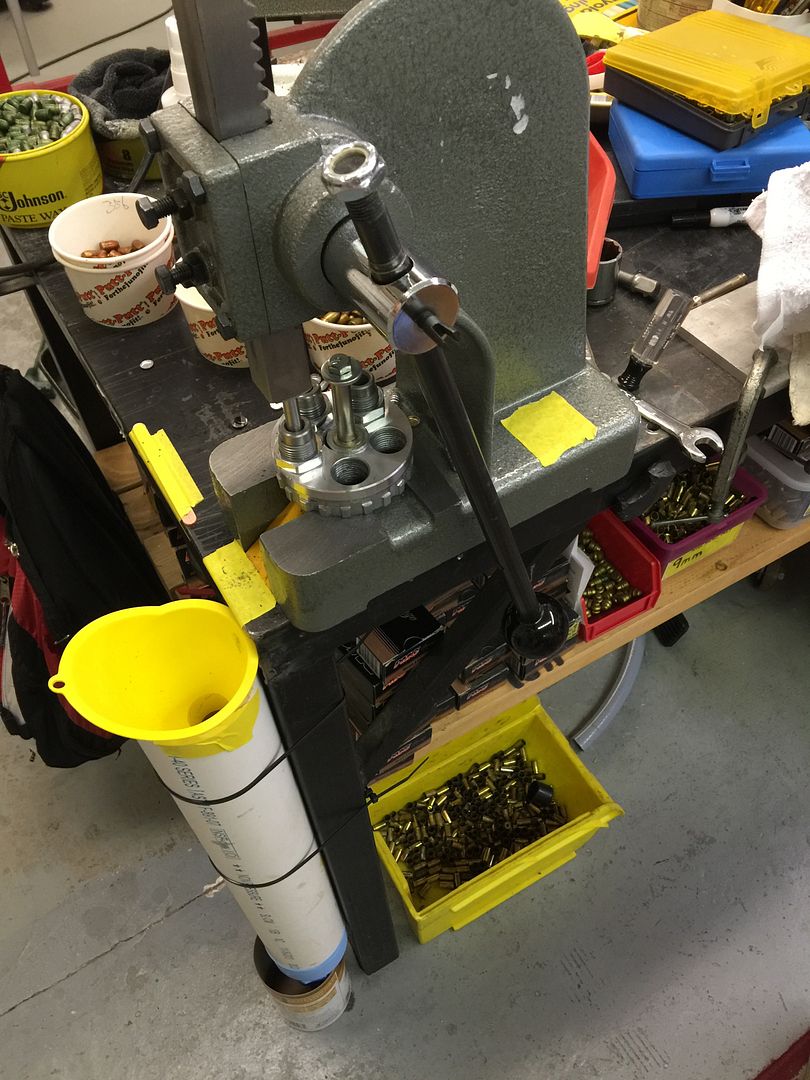

Or has anyone worked up a means of holding a lube die and top punch in an arbor press to top punch boolits?

Thanks, Mark

|

|

|

Reply With Quote

Reply With Quote