So I replaced my $18 toaster oven with this one to have large interior, higher wattage elements and convection . Using a PID so temperature control is fine Convection fan only runs when set to bake which is fine however fan also cuts off and on with bottom ( Bake) heating elements and also of course cycles (pulses) as PID cycles power.

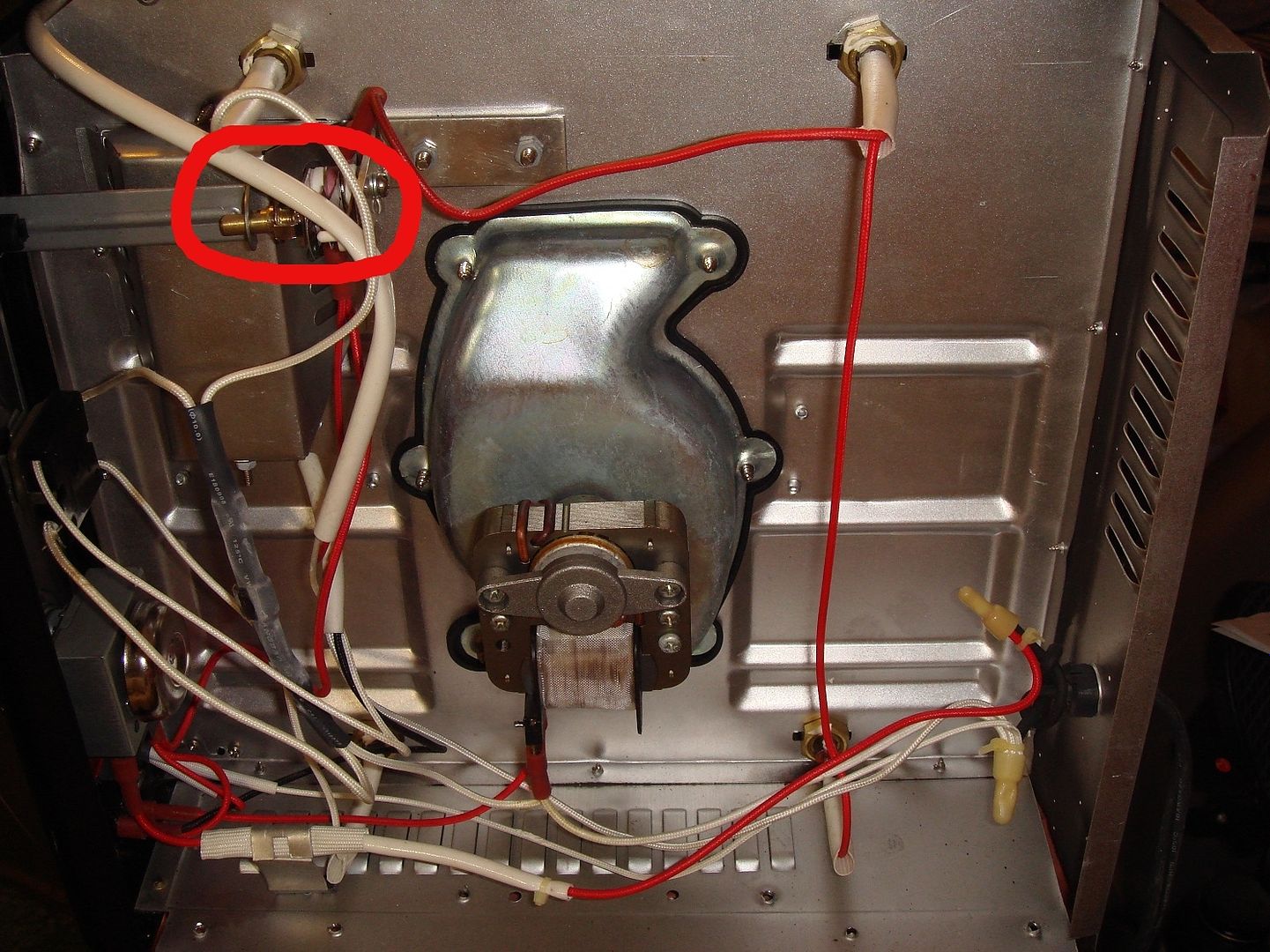

I baked a few batches and all look fine and past hammer test. Can not deside if it is worth the effort to open it up and wire the fan to a seperate power line so it runs full time. With fan running full time I guess I could use the Toast Setting so that both top and bottom elements heat which means twice the power available.

|

|

|

Reply With Quote

Reply With Quote