Yo, Adrien;

I have waited YEARS to say that!

.

I'll bet that lead-free solder is available in Old Blighty - is that what you use in your alloy?

Ed

|

|

|

Yo, Adrien;

I have waited YEARS to say that!

.

I'll bet that lead-free solder is available in Old Blighty - is that what you use in your alloy?

Ed

Echo

USAF Ret

DPS, 2600

NRA Benefactor

O&U

One of the most endearing sights in the world is the vision of a naked good-looking woman leaving the bedroom to make breakfast. Bolivar Shagnasty (I believe that Lazarus Long also said it, but I can't find any record of it.)

Toymaker writes

I just thought I should point out how lucky you are to have grey hair mine is pure white! ~probably due to all the worry about leading and alloys.Haven't played with this yet, but I will. Just thought I'd pass it on before the gray hair got in my way and I forget.

Interesting point your colleague makes about the silver stuff turning black overnight if he is right then it may explain the patches I got out of the muzzle end which appeared to be heavily leaded; perhaps it was fouling after all although some I rolled between my fingers did not break up as I would expect of fouling.

Having said that I have been told that the Swiss powder does give a very hard dry carbon deposit which I suppose could, hard wise, be mistaken for lead if it had streaks of the stuff in it to start with? Perhaps other BPCR shooters can confirm this?

C'est la vie

I am going to try and get some short range time to test my loads, leading and acuracy in the near future, might have to be 50yrds thought. This time I will redo the leading test with pictures at the time. I shall try to match your friends results but do not hold out much hope.

All the best

Adrian

Echo writes

Now you are going to think I am a real dumbo; it has never occurred to me to use lead free solder, I have been buying pure tin sticks at approximately £27 ($40) per Kilo, not easy to find.I'll bet that lead-free solder is available in Old Blighty - is that what you use in your alloy?

Had a quick look on ebay and the reels of tin solder appear to be just a bit cheaper at about £26 per Kilo plus postage. May be cheaper in larger quantities though.

Dose this plumbers solder (which appears to have other constituents) work as well as the tin sticks?

Adrian

PS Hope I haven't upset Toymaker with my hair quip!

Instead of mentioning where the cookies are hidden, here's the cookie jar location....

Modifying Molds on Cast Pics

http://castpics.net/dpl/index.php/th...odifying-molds

Title

Beagling

Beagling a Mold - Temporary Mold Enlargement

Fixing Lee Molds

How to Hone out a Mold

Leementing a mold by BS

Leementing Kit Documentation

Lyman Mold Tune Up

Mold Lapping

Mould Maintenanace

Belle, Belle, Belle!

Purty Gu-ur-url!

I use a T. Ballard adjustable mold that is currently set to drop 530gr. bullets. If you wipe between shots a lube cookie is not necessary. However you can use a cookie if you want. From my experience when paper patching leading is nonexistent. Once I started patching my Lyman 457132 Postell mold is nice paper weight.

M71

Those are nice looking cartridges.

U.S.A. " RIDE FOR THE BRAND OR LEAVE!"

Adrian,

NO LEADING. Not even a hint. Zero, Zilch, Nada.

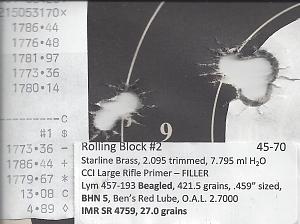

Check those average velocities and standard deviations!!

YES - PURE LEAD. No tin, No antimony. The softest of my roundball lead.

I can't go any higher because a 1/2 grain increase in powder will push me over the maximum safe pressure.

100 yards, iron sights, off the bench. Clean bore, 5 shots and clean the dickens out of the bore for the next group.

90°F, 54% humidity, 29.92 inHg and falling (BIG storm coming in), 3 mph wind left to right.

Hi Toymaker et al

Sorry I haven't posted for some time, I haven't done anything worth commenting on except a short range shoot yesterday at 300/600yrds. 25:1 lead with a 60grn Swiss#4 charge. Result very light leading at the muzzle and nothing at the chamber end. Very different from the long range I have done with a 72grn charge which did produce some leading even at the chamber end.

So i wonder if the velocity is my problem together with not so good a lube?

Some good news is that I might have tracked down a 100yrd range where I can do some proper testing of my ammunition, seeing my groups and getting a zero for my Holbrooke sight which I discover is calibrated in degrees and not moa! I shall keep you posted if you are still interested.

Getting this black powder reloading right certainly takes time, as everyone keeps telling me, still I am happier now with my alloy for the boolits.

Adrian

PS. toymaker, I notice from your last post that you use IMR SR 4759. Is this not a nitro pistol powder? Dose this not push up the velocity enormously?

PSS. Some really nice pictures on some recent posts and as always some more great ideas.

Adrian - agreed, sounds like your lube isn't lasting until the end of the barrel. That can be a problem with the longer barreled rifles. Now that you've found an alloy that working it sounds like time to play with the lube. Friend of mine gave me this recipe for BP that he uses for long barreled, long range rifles. He's good too and one of those guys who, if he recommends it you can "take it to the bank." I haven't tried it yet, but it's on the top of the list. 8 ounces (weight) beeswax, 6 ounces (volume) neatsfoot oil, 1 bar of Neutrogena soap. Melt and mix in a double boiler. If your lube bands are narrow and you need more stickiness, you can re-melt add a teaspoon of anhydrous lanolin, test, re-melt, add more if needed, test, etc. (Neutrogena is an old, very popular cosmetic soap).

Do you have any idea what velocity you're getting? Just as a guess I'd say you're getting something around 1,250 to 1350 fps. That seems to be the typical range where things come together and accuracy is the best. Not impossible that velocity is a contributor to leading, but I'd go after the lube first. Remember above, I got wildly high velocities from pure lead bullets and no leading due entirely to the lube.

Yes, IMR SR 4759 is one of those border-line powders with applications in pistol and rifle loads. My usual load is 23.5 grains under the lighter Lyman bullet. Since it has been discontinued I've been testing IMR 5744 and have gotten very similar results, so when my 8 pounds is gone I have a go-to backup powder.

My activities have been put on hold for a while. Seems I've had a heart attack, actually a series of them. Thought I'd contracted an upper respiratory allergic reaction and I put up with it for 9 days before going to the hospital. Now it's rest, heal, a mountain of pills and therapy to come. Missed two matches, will likely miss all three in August plus the Nationals in September. Feel good, but not a happy camper.

Tony

Toymaker et al.

Well I finally got the opportunity to shoot 100yrds to test my ammunition.

Boolits all 25:1 which is 4B according to my pencils or 9BHN according to DougGuy's Pencilhardness Versus lead alloy hardness chart (on this site). Postell bullet mould nominally 535grn.

All Swiss #4 All with proprietary lube (as before) worked well into the grooves.

Loads

60grn,64grn,66grn,68grn,72grn

All fire formed,recently annealed, neck sized cases.

I zeroed the sight using the 60grn, having done so the above is the 60 grn group at 1 3/4" centers. There was throughout the shoot quite a stiff left to right breeze.

The sight setting for elevation is the same for all groups including the 60grn. I was shooting for groups of 5 not bulls.

White patches show 64grn group 2 3/4"

Black patches show 66rgn group 1 5/8"

To the right (I moved the windage over by three minuets right to keep the groups apart) is the 68grn group 2 3/8"

To the left (I moved the windage right by 7minuets) the 72grn group 1 3/8"

The first thing that surprised me was the drop in elevation as the charge went up?

64grn is about 1" down from 60.

66grn is about 1 1/2 down from 64.

68grn is about 2" down from 66

But 72 grn is about 1" up from 68!

Each group was 5 rounds, the rifle was wet patched after each shot. I think the wind was having an effect even at such short a range.

So the 66grn looks the best for short range (up to 600yrds) and the 72 for long (up to 1,200yrds) However I think further testing is required and this I will do on Wednesday this week so any ideas you have on how to improve the test and the results would be most welcome.

Now for the leading which has been another issue for me. On this occasion after 30ish rounds there was very little leading at all.

You can probably see one or two small pieces of lead on this tight patch which was put through after the initial clean up. Apologies for the quality of the picture. This is a significant improvement on previous leading which I put down to the softer alloy used, an increase in the lube and the more careful wiping out between shots. Not being a competition I had more time to keep the fouling down. I also inspected the other patches as I went along and there was no sign of leading.

Adrian

Last edited by loadedbutbroke; 08-18-2015 at 03:07 AM. Reason: Mistake in load wight 74 is actually 72

Short and sweet and possibly covered above.

Use 20:1 alloy. Purchase it directly from RotoMetals and save yourself some aggravation.

Cast to .459 and/or size to .459 (My Pedersoli likes .459) Be mindful of the short 0.17" Leade.

Use Black Powder bullet lubricant in the bullet lube grooves. I use 2:1 beeswax to tallow.

Use black powder if possible.

The 1:18 twist really likes long heavy bullets. Bullets should be >480 grains.

That's it.

slug your barrel and feel for any rough spots while doing it. I prefer to slug a barrel with a slug tight enough to do the job of getting the correct bore dia., but still allows me to push through by hand. If the barrel has rough spots, I fire lap, recheck, etc.. until I have a smooth barrel. Accuracy improves greatly. I use an RCBS 405 FN mold with gascheck and 20 : 1 mix, bullets drop from mold at .4597. I size to .459 and gascheck for my Sharps #1 Business Rifle and smash clay pigeons

set on a hill side at 300 yds. I seat the bullet just kissing the rifling on that rifle, that's what it likes the best.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |