I wish I could change the title to reflect that I'm converting once-fired 7.62x51 milsurp brass instead of commercial 308 Win. The commercial is thinner and I don't think it will need neck reaming/turning at all.

This post is edited to show my most recent method of converting once-fired 7.62x51 milsurp to 35 Rem.

1. Open 7.62x51 neck to 358 in a 358 Winchester sizing die.

2. Size in 35 Rem die with decapper removed. I take several small strokes and rotate the brass a few times to help it size evenly.

3. Size neck using Lyman M die.

4. Chuck brass (base up) in drill press.

5. Turn neck OD using jig. Jig is a high-speed steel lathe tool and a drill bit in a piece of scrap wood.

Turned neck:

6. Insert bullet in case neck and chuck in drill press. The bullet lets you tighten your chuck securely without distorting the brass.

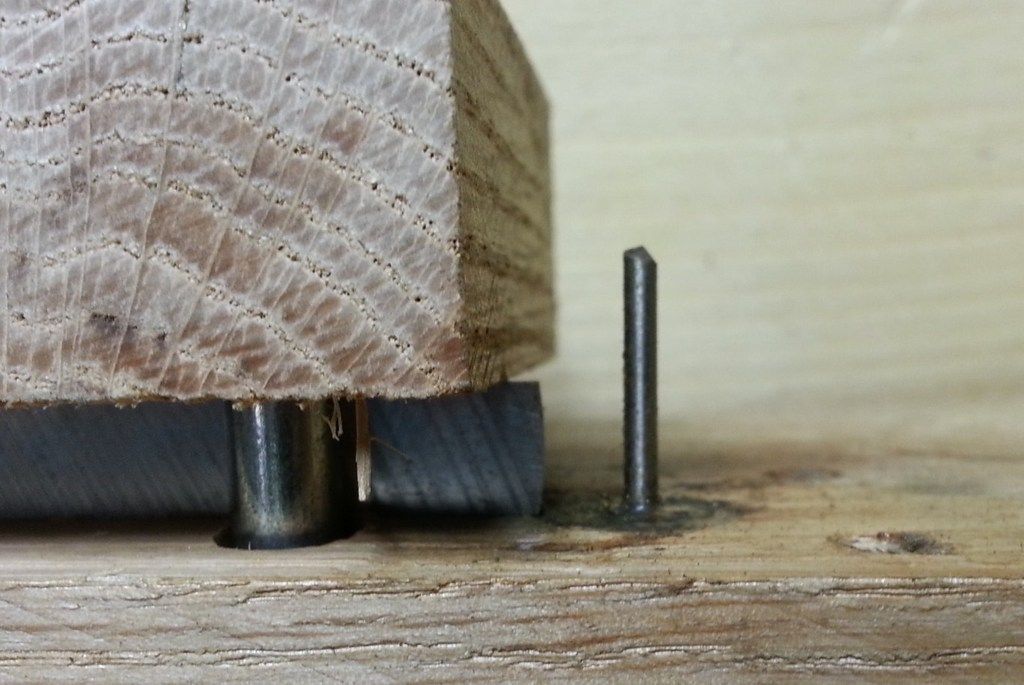

7. Turn base using jig. Again, HSS lathe tool and a drill bit just large enough to fit in the primer hole.

Tool is ground so that only a tapered section of brass is removed above the point where the base ends.

Should look like this:

8. File and sand as desired. I take two swipes with a file at the point where the cut parts meets the uncut part of the body, and then a piece of 400 grit for a few seconds. I really don't think this is necessary, but it looks better.

9. Trim neck to final length.

I cut a piece of factory 35 Rem and a piece I converted using this process. Factory brass is on the left.

I think it will work.

|

|

|

Reply With Quote

Reply With Quote