I recently aquired a Lyman 4 cav 452374 mold from a member here, the mold had been purchased as part of an estate sale and had never been used by the Member.

He did mention that the mold had seen some rough use, which was refelcted in his asking price, which was more than reasonable!

A deal was struck and the mold shipped to me.

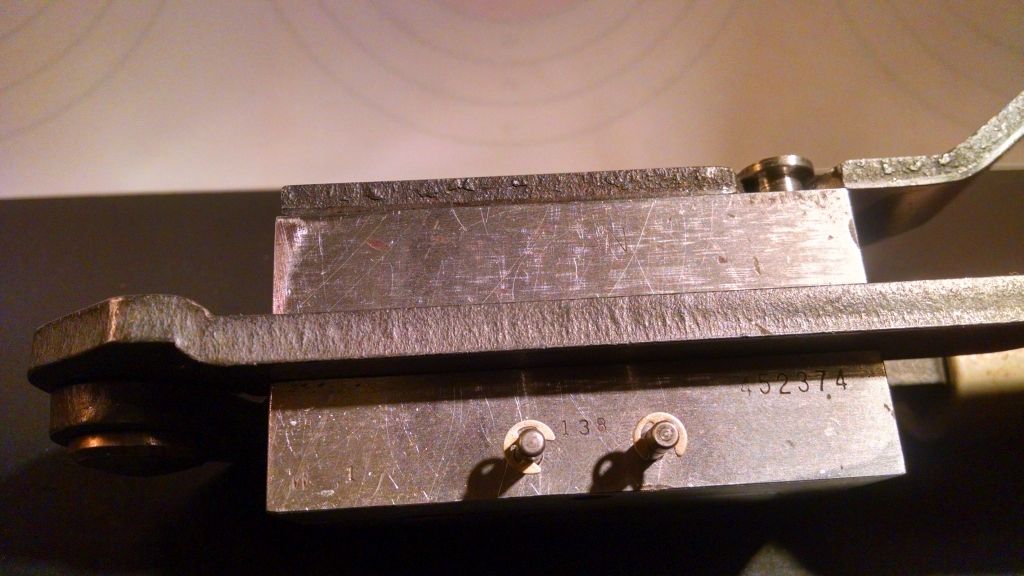

He wasn't kidding! Cavities were spotless but the outside of the mold was in poor shape, I actually replaced the sprue plate with a spare I had on hand because it was so badly burred up from being hit with a steel hammer!

bottom of mold looked like the PO used it to open another mold in the same manner, must have broken the hammer on this one, LOL!

A little clean up got the mold usable and I cast a dozen or so just to check size.

All was well but it did cast a touch large as there were still some burrs along the bottom of the mold.

Since this was a project I didn't waste any more time on it and did what I intended to do when I bought it: I shipped it to Erik at Hollowpointmold.com with instructions to convert it to a 4 cav HP mold using his insert system.

Erik and I had a couple conversations about the mold, mostly both of us laughing at how any moron could abuse a mold like this, and he advised he would have to clean the bottom up before he could do the conversion but the funds I sent would cover it all.

A week later the mold arrived in my office mail and looked great! Erik had suface ground the top & bottom of the mold as well as both sides of the sprue plate so it sat dead flat on the mold!

The insert system looks great and very solid, he also added a wave washer to the sprue plate, the PO had drilled and tapped the pivot bolt 1/4-20 for some reason and I had added a Stainless Steel button head allen bolt, changing out the odd looking 3/8's hex bolt that was in it when I got it.

Mold opens and close's much better with no light showing through any of the joints!

Erik has done several other mold projects for me in the past, this is the most extensive work he's done, and for those who wonder about conversion work or or other modifications Erik offers please feel free to move forward as Erik is da man for this type work!

Felt like **** yesterday but this morning I feel much better and hope to fire up the pot to make a few for testing, I'll update the post as soon as I do this to give detail on the boolits as cast conditions.

|

|

|

Reply With Quote

Reply With Quote

Casting, Reloading & Shooting

Casting, Reloading & Shooting