Today I decided to inventory the various 45-70 rifles I own with regard to their internal barrel dimensions

Measuring "bore" diameter proved to be difficult because of the various number of lands and grooves and the twist on the driven slug.

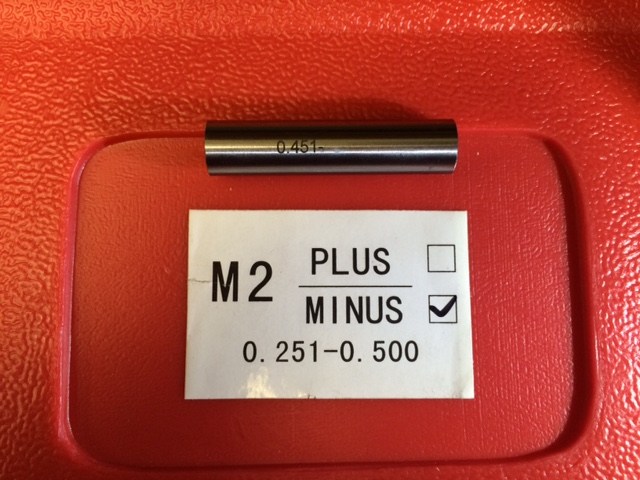

I ordered a set of precision ground pin gauges .250 to .500 (negative ground)

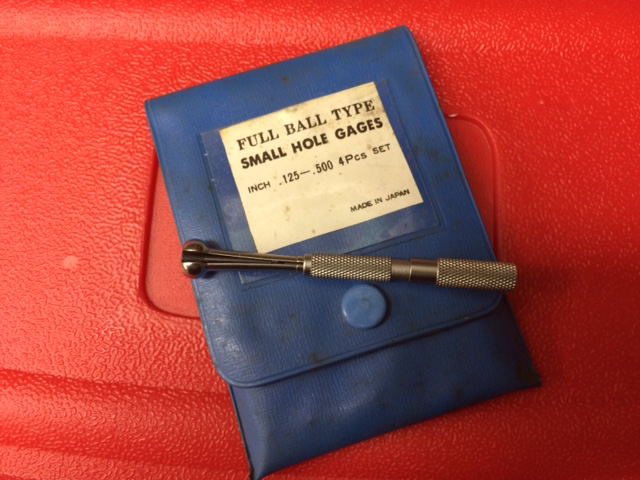

Using these pin gauges and verifying the numbers with an expandable Ball Type Hole Gage I was able to arrive at relatively accurate numbers.

Once I knew the bore, I wrapped various pin gauges with two layers of #9 Onion paper that I sourced through Buffalo Arms

Using this method I arrived at the exact diameter I needed for a bullet if I wanted the bullet and the paper to ride on the lands. To this number I'll add X inches to arrive at the casting mold dimension I'll need.

I'll then turn a "D" Reamer on the lathe and proceed to cut a paper-patch bullet mold.

Does this sound like I'm headed in the correct direction?

45-70 Rifle Barrel Dimensions

Paper Patch #9 Onion / 25% cotton = .0016” (Double Wrap = .0064”)

RIFLE BORE GROOVE BULLET FINAL

PEDERSOLI

Rolling Block (Pistol Grip) .4500 .4570 .4450 .4513

PEDERSOLI

Rolling Block (Straight) .4500 .4553 .4440 .4504

PEDERSOLI

1874 Sharps .4490 .4575 .4430 .4488

H&R

1884 Trap Door Officers .4490 .4575 .4430 .4488

WINCHESTER

1886 (Japan) Take-Down .4500 .4563 .4450 .4513

WINCHESTER

1885 BPCR (Badger) .4500 .4560 .4450 .4513

“BORE” measured using negative gauge pins

“FINAL” is negative gauge pin wrapped twice with patch paper and a tight fit without paper tearing.

3-21-15

|

|

|

Reply With Quote

Reply With Quote