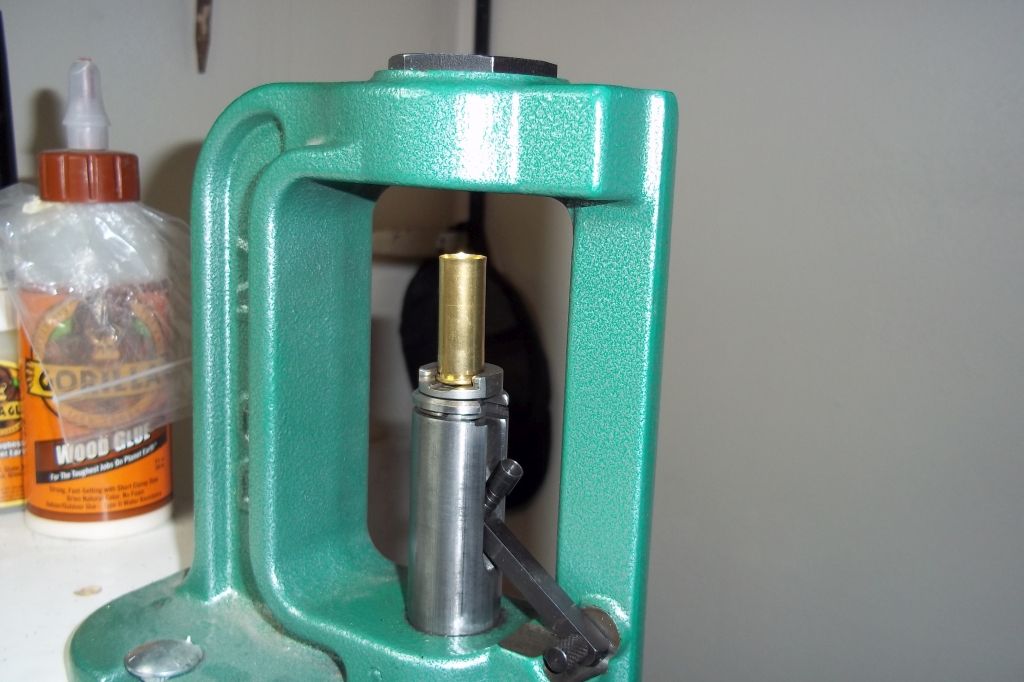

I have a 38 Spec. partial die set. Need primer seating die, bullet seating die, and a de-capping pin. Am considering making the dies and have a question about the primer seater die. Does the top end of the die have to extend above the rim so far? Would it work if it only extended 1/4-3/8 inch?

Dummy me, forgot to specify that these are 310 dies. The priming dies I see in pictures online seem to be about 1/2 inch long above the rim cut.

|

|

|

Reply With Quote

Reply With Quote

Casting, Reloading & Shooting

Casting, Reloading & Shooting