|

|

|

Von Gruff.

Exodus 20:1-17

Acts 4:10-12

As for the barrel I had got onto one that was a take-off and had been chambered for the a shortened 405 Winchester --the 405 x 2.2. It had been fitted to a Marlin Lever action so needed som work on it. The thread was much smaller than the Enfield action so sleeve was machined up and threaded onto it. One downside was that it had two dovetail cuts on the underside and one for the front sight. I had ordered a reamer to lengthen the chamber but had to keep in mind the Lee Enfield magazine length. I decided to cut the chamber to 2.410 and trim 405 Winchester brass to 2.405 and with the cast bullet I intended to use I could load to a COAL of 3.045 inches. LE ammo is 3.07. This case length would also suit a jacketed bullet.

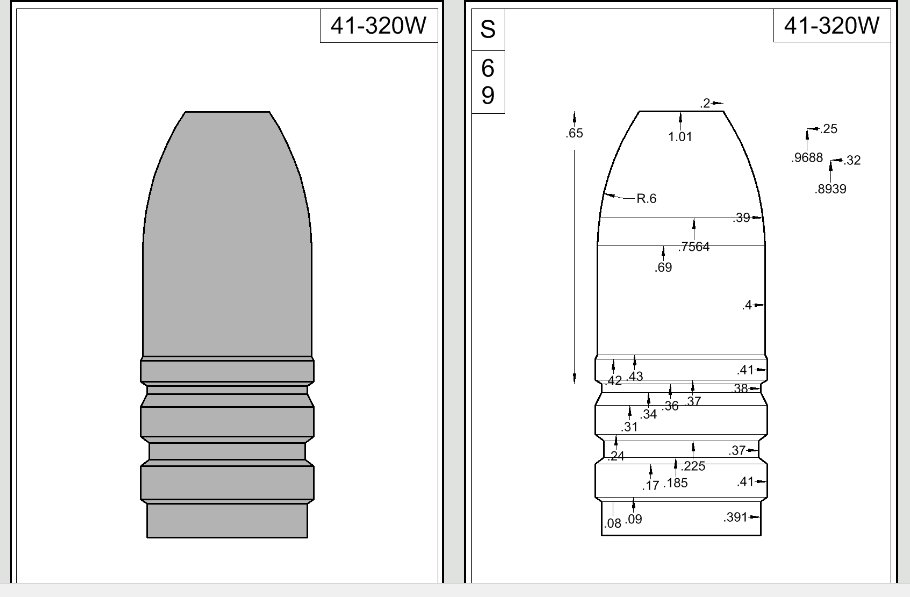

This is the cast bullet ( standard dimensions) but the mould has been ordered to suit the barrel dimensions.

Last edited by Von Gruff; 07-10-2015 at 07:13 PM.

Von Gruff.

Exodus 20:1-17

Acts 4:10-12

I started the barrel inlet but can not finish it till the rechamber is done, it gets timed to my action and snugged into place. In the meantime I decided to make a couple of extra tools to help with the channel finish. To date I had been using parts of old barrels as push scrapers but that is not always the best way to do it so I cut a 3/4 inch lengths of the end of the barrel bits, drilled them to 7mm and hardened them

Some long 1/4 in bolts were set for the handles and 3 nuts were ground down so they would be a back nut and unobtrusive for scraping. Three lengths of 7/8 in dowel were drilled, the heads were cut from the bolts and some fins made on the shank to hold them into the handle

A bend on the bolt and the handle tapped into place and I have three sizes of scrapers. They may not look it from the pic but the bends are all the same and the scraper heads are reversible and sharpenable so should do for quite a while.

Von Gruff.

Exodus 20:1-17

Acts 4:10-12

To fix - hide the dovetails a piece of steel was filed to shape and tapped into the first one

A bit of cleaning up and it would almost hide with a touch of blue

The centre one was done the same but would be used to position the barrel mounted sling eye. A piece of shotgun barrel was used to make a base for the sling eye

a hole was drilled into the dovetail, the sling screw was cut and a groove made round the stub so when it was all soldered together it would make a good bond.

Von Gruff.

Exodus 20:1-17

Acts 4:10-12

I was perusing another site where there is a great deal of very good Lee Speed data and saw a thread on the trigger guard having a waist ground into it and while I had seen it before on Mausers and had done it on my DWM custom I hadn't seen it done on Lee Speeds so this morning I took the TG off my 400 and the one from my 303 and ground on them a little. I kept the 400's a little less curved to denote the heavier cartridge but both are markedly different to what they had been

I had been unable to source ebony here in NZ but a friend has got some for me off shore so I decided to do a forend tip on the 400 which I hadn't intended to do and that meant the plain walnut grip cap would not do or match the tip so will be replaced with the last small piece I had in the shed. I have cut it as a grip blank and will be working on over the next day or two

Last edited by Von Gruff; 03-07-2015 at 09:03 PM.

Von Gruff.

Exodus 20:1-17

Acts 4:10-12

With that in mind I sorted through the router bits and by changing the end bearing to a smaller size and being just a bit careful I was able to sit the router in the vise and by holding the cap with a piece of dowel only had it thrown out of my hand a couple of times but goterdid. Will shave the top down when it is installed.

Von Gruff.

Exodus 20:1-17

Acts 4:10-12

Being a carpenter most of my years and haveing seen a few guys lose fingers.

Your router work scares me I'd never try that by hand.

Watched my father lose a finger on a radial arm saw. It was turned off and just barely turning when he reached in to get a small piece of wood out.

Those who choose violence as a first option are typically confronted by somebody else using violence as a last resort.

Live a good, honorable life. Then when you get older and think back, you’ll enjoy it a second time.

Do not confuse my being polite for weakness.

Using MX Linux 21

From the free state of Idaho

Von Gruff.

Exodus 20:1-17

Acts 4:10-12

Awesome thread and work. Thanks for sharing this. Can't wait to see the finished rifles.

A work of art

wow, i am in awe of your skills.

When you read the fine print you get an education

when you ignore the fine print you get experience

Having got the new ebony grip cap made for my 400 I had to cut the walnut one off.

It took a little time to file the saw cut back to the stock wood and make it flat for the new cap but once that was done I made new brass dowels and got it epoxied into place.

A trim up of the stock wood with needle files and fine paper had things reconciled again. I had made the new cap a couple of thou smaller so the stockwood could be blended back into the cap dimensions.

Am pleased I decided to change things as I like the contrast of the new cap. The plain caps had been used initially because the original BSA 375x2 1/2 had a grade of finish without a cap. I had wanted to protect the end grain and had done the 400 the same but being able to get the ebony changed my mind before I had gone too far.

Last edited by Von Gruff; 03-09-2015 at 02:46 AM.

Von Gruff.

Exodus 20:1-17

Acts 4:10-12

You are a more patient man than I Gruff. Inletting a Lee action like that. Phewph!

Thermal underwear style guru.

"Exclusive international distributor of Jeff Brown Hunt Club clothing."

Supplier to the rich(?) and infamous.

Cheers from New Zealand

Jeff.

Realy nice. Thanks for sharing.

like your homemade barrel channel tools great idea, i made my own too but with much more effort than yours took,, realy great !!!.

The 375 303 looks great.

When you read the fine print you get an education

when you ignore the fine print you get experience

hi VG

I really like the look of the 375 with the WR contour on the barrel ,pitty the wood didn't stand out after all the work ,all in a wounderful result

Cheers Peter

Superb! No, very super-duper superb!

What marvelous work. Somebody has to do it! Just think, there are people who do all this for an investment cast action! There are also people who get artistic grants from governments for work which has the artistic qualities of a chocolate mouse by comparison.

They are splendid rifles, and the Long Lee-Enfield is my favourite Lee action. There are very few shots in ordinary deer hunting for which you can honestly blame failure on such a rifle, or on its cartridges, either original or most that are devised for it. A rifle done exactly as you have done would be all of that, so I hope you don't mind me floating some ideas.

I think I have an ambivalent attitude to the dust cover. It is an excellent thing for the iron sight user to have, but it is impedes the already difficult task of mounting a scope. I positively dislike the Scout scope system, with shorter eye relief than a handgun scope, but mounted with the objective forward of the magazine. Would a scope be in keeping? There were pretty good scopes (compared with no scope at all, of course) by the year the first British Lee was hatched, and I would suspect that a small minority of civilian shooters made experiments right from the start. I don't see any way of keeping the dust cover (other than in an envelope clearly marked for posterity), but if you want to make a side mount you have the two screwholes on the butt socket and the ejector screw hole to play with.

I am not quite an ebony enthusiast, although I have had a couple of thick pieces lying about for thirty years. It expands, contracts and cracks more than many other woods, especially when a thin piece is crossgrain to walnut. My preference would be horn, which is amazingly tough and stable stuff. and you can buy blocks and slabs fairly easily on eBay. The same applies to ebony, and "guitar fingerboard" will find it. But watch out you don't get one already grooved for the little piece of profiled wire they use to choke off a note at the desired pitch.

Here is a website for knifemakers, with a very wide range of exotic woods, horn etc. I have always thought that modern "damascus" steel is a bit of a con trick for knife blades. You can get far better modern steels, and this supposedly miraculous art has become far more commonplace of late. But a piece of damascus, shaped and acid etched, can make a most attractive pistol grip cap. If you want a metal reinforcing crossbolt at the rear of the forend, cutlery rivets are excellent. They aren't rivets at all, but blind nuts designed to be screwed onto a bit of threaded rod, and the end with the slot filed off flush with the surface.

http://www.knifemaking.com/default.asp

Your moulded edge grip cap is a thing of beauty. I agree, I would beware of doing this on a full-scale router. Fixing it to something may keep your fingers safe, but the cap can still shoot off into orbit with a notch in it. I think I would use the Dremel router or router table, which is far less likely to do you damage.

I can't see that the Enfield butt socket is a weaker or less accurate way of fitting the butt than any other. The trouble is the forend, with its tendency to press more or less on the front of the socket with differences in expansion. I believe I would fit a long barrel band for scope base or rear sight, and I would glass bed it into the forend so that definitively fixes its right position. Then I would inlay a piece of firm rubber sheet into the rear of the forend, so that it perpetually exerted pressure on the socket.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |