I wasn't sure where to post this thread as it could have gone in a couple of sections but being a project in cartridge and rifle I thought it might be best placed here.

I had been wanting a big brother for the 303 Lee Speed styled sporting rifle http://castboolits.gunloads.com/show...Sporting-rifle for some time and with conversations with a couple of LE enthusiasts it seemed there were to main contenders with one being the 375-303 and the other on being a 40 cal of some sort. After quite a bit of discussion it came down to my preference for the 40 cal as I had not long sold on the 404 Jeffery I built and was feeling the gap at that end of the gun rack.

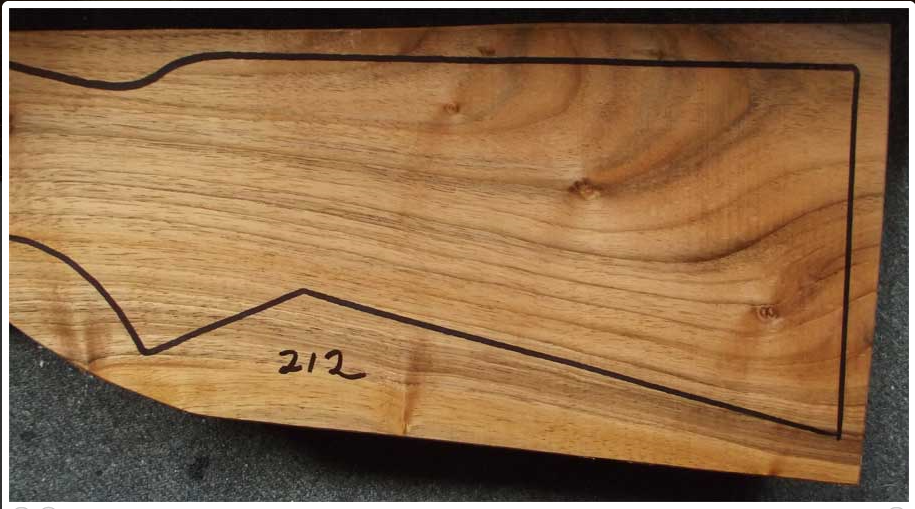

It all hinged on hearing about a short chambered 405 Winchester barrel that was a take-off from a marlin LA project so my preference was backed up by the availability of the barrel and the offer of a nice BSA commercial MK l action from a forum member (another forum) who had also voiced an interest in a 40 cal LE

More on the cartridge later---

So the action turned up and it all started in earnest (maybe a bit slower than earnest but underway nevertheless)

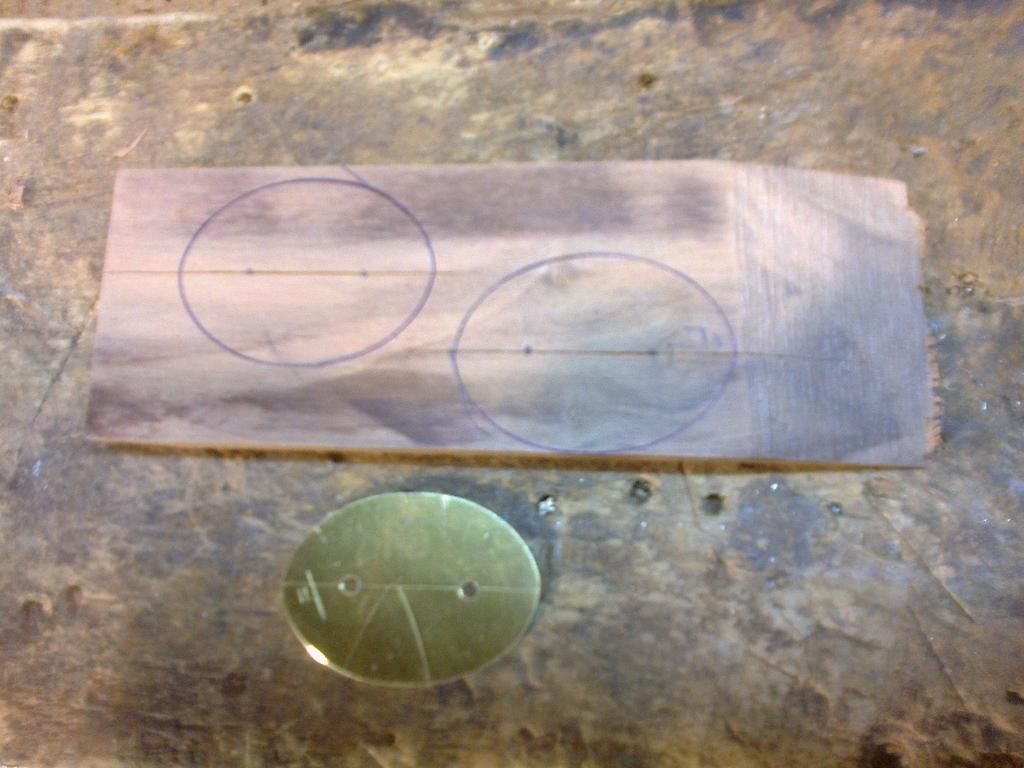

This was the action as received

I had a few bits to add to it so am just looking for an early magazine and a dust cover now. I am not going to use the magazine cut off so will stock it without the recess cut out.

|

|

|

Reply With Quote

Reply With Quote