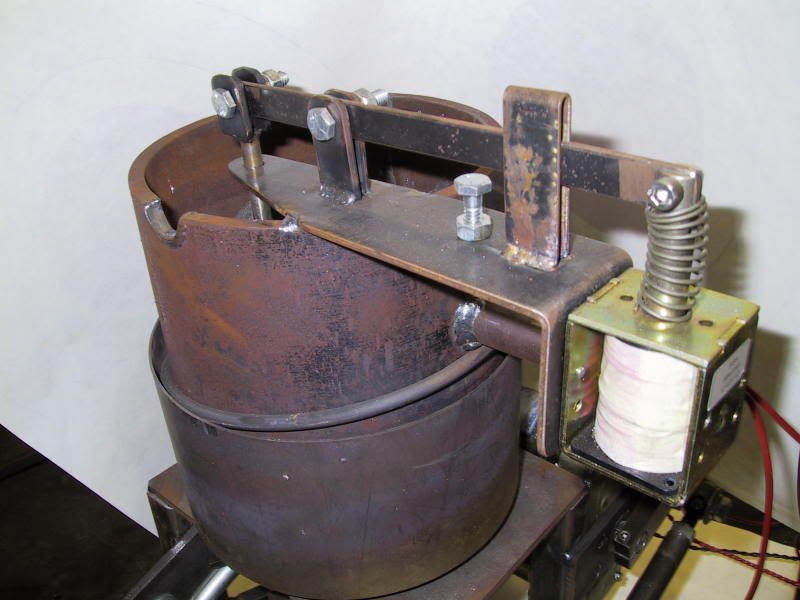

I am building a bottom pour smelting pot from a 20# propane tank. I have searched this forum and gotten some great ideas and designs. I have in my head that mine will incorporate many of these designs but be unique in many ways.

My question (to the more informed than I) is about galvanized bolts in the valve. I can not find any bolts that will do what I am planning that are not galvanized. Will there be enough zinc or other contaminates to ruin the lead? Is this even something I should be concerned with because I do not think that the galvanizing will be effected by the relative low temp of the lead?

I am fairly computer illiterate but will try to figure out how to get some pictures of my pot posted when I am done with it. Assuming it works and does not end up in the junk iron pile beside some of my previous projects.

|

|

|

Reply With Quote

Reply With Quote