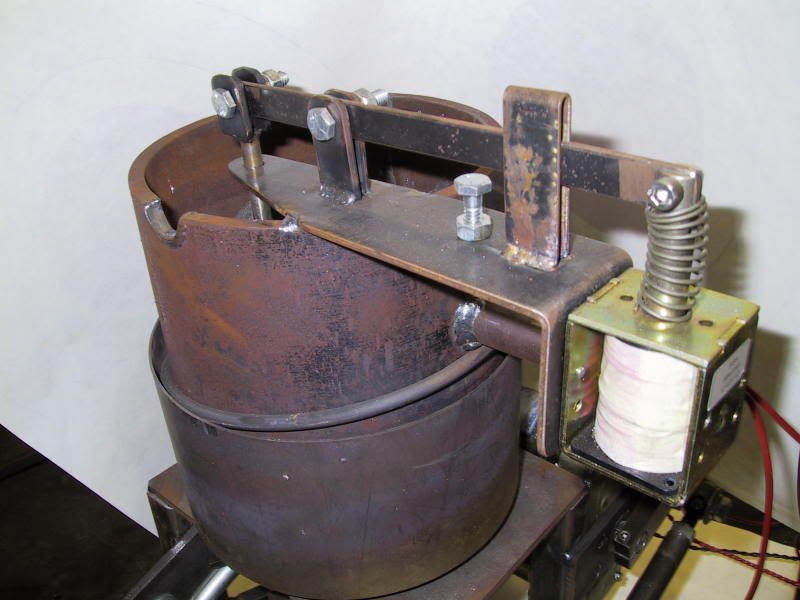

Is it an outlandish idea to create a solenoid flow controlled bottom pour pot? Should be easy enough to adapt to a large Lee bottom flow pot. I have had this idea for more than a few years now.

My question is, in your opinion, could this be of benefit, or is it just complicating an already simple and sound system. I suspect responses will be be varied. I am especially interested in any safety concerns.

I have a picture in my head of how I believe I would do it, but please add any ideas you might have as well. I am assuming that I would not want to overheat the solenoid so some separation and shielding for the solenoid would be necessary. I think a flow control rod could be constructed that would not transmit too much heat to an overhead mounted solenoid.

A silly idea, or may it have some merit.....again keeping casting safety in mind? Someone may already be doing it for all I know.

Mike

|

|

|

Reply With Quote

Reply With Quote

HATCH

HATCH