Always with the spirit of experiments i am made another daring gift bullet mold of custom marketing is like a Miss Universe with fishnet stockings and miniskirt underarm.

This is a bullet mold nose pour molds adjustable to make patched bullets manufactured by KAL Tool & Die - Canada

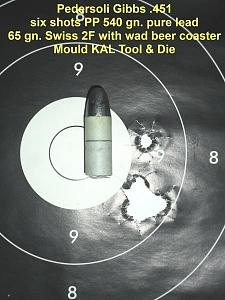

This a good shot

|

|

|

Reply With Quote

Reply With Quote