Per Boolits members musings, there's an alternative....

...the Mr. Bullet Feeder, right?

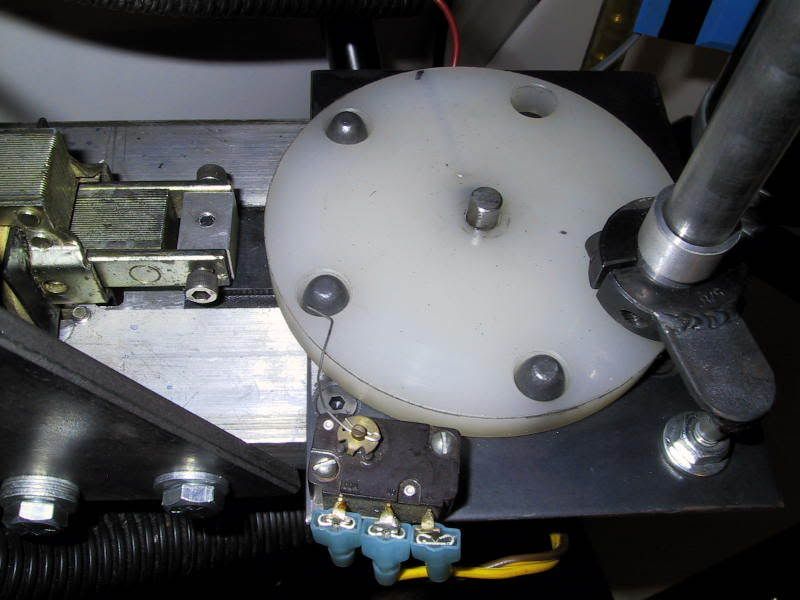

Either for automation or this collator, you'd probably want the Magma Bullet Feeder anyway.

It sounded asif this was successfully designed. Though it sounded like the caliber specific parts could end up being pricey, relatively speaking, it's not too bad. The other big makers explicitly state no cast boolits, just jacketed fodder.

I was just thinking how the repetitive stacking and orienting of boolits gets annoying and is time consuming--at least compared to how fast you can pull the handle.

This would be a valuable item for a group buy, imo

|

|

|

Reply With Quote

Reply With Quote

HATCH

HATCH