Alvarez,

Looking at a few different presses, including the one on my bench that has been in service for over 50 years, I have a few items to offer:

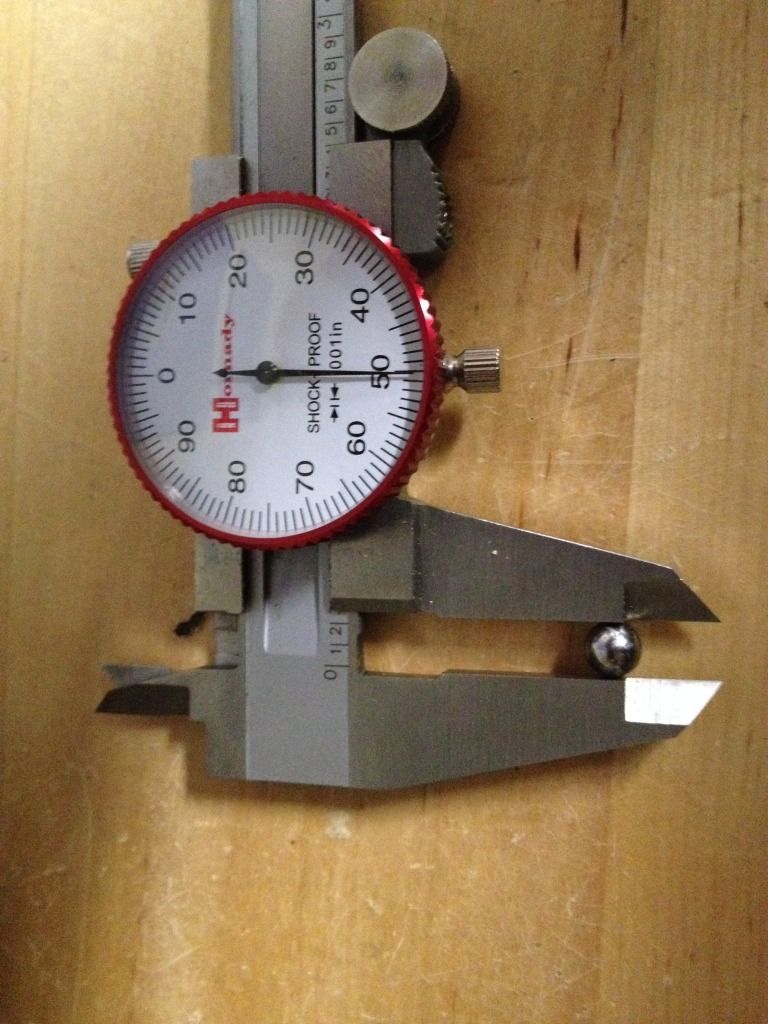

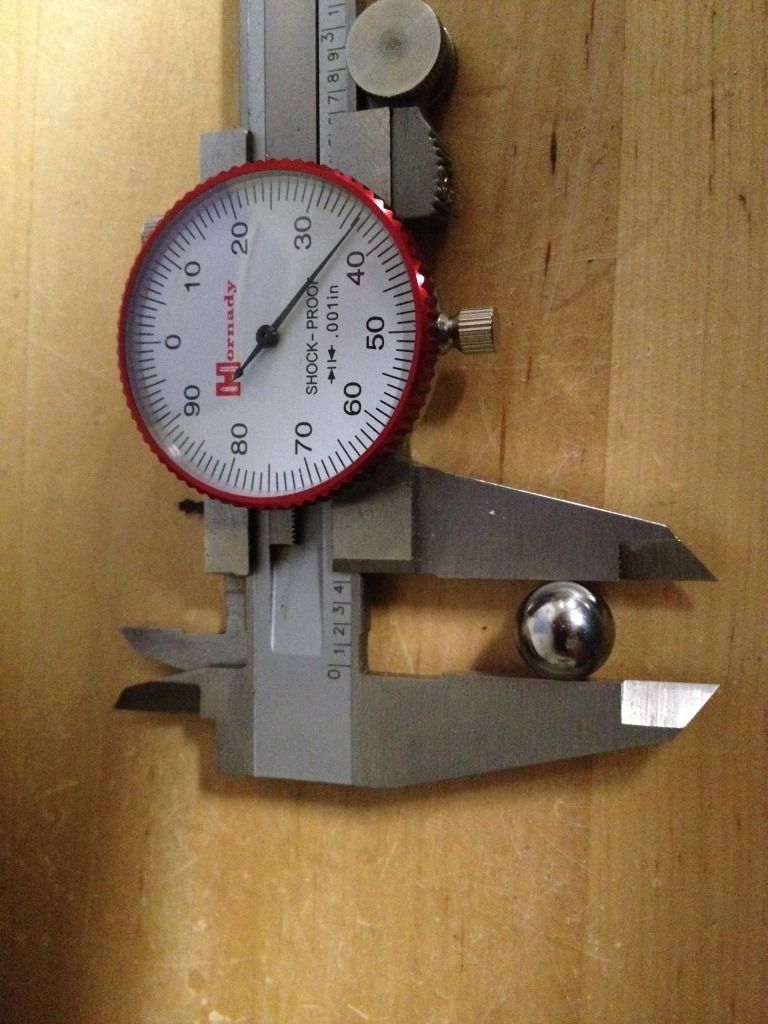

1) If the ball bearing in the tower is stainless, it probably didn't come from Mr Corcorans stock. My stock of 1/4" bearings are chrome plated steel. They wear, hopefully helping to preserve the press turret.

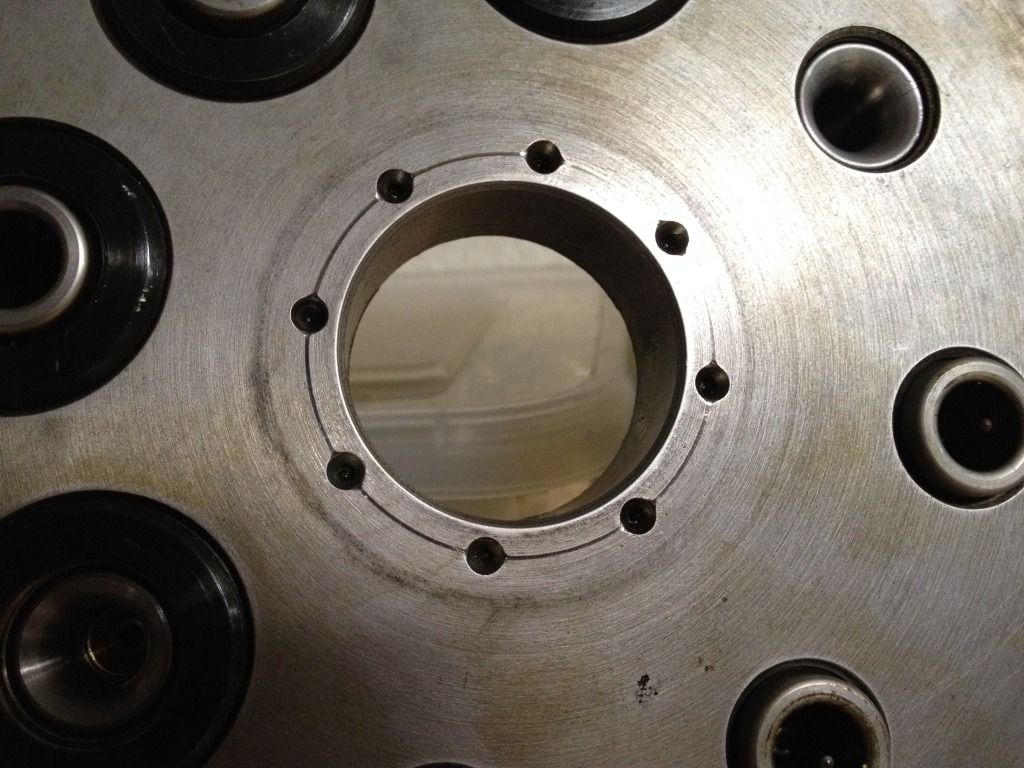

2) If the spring holding the ball in the tower is too long, the ball will not be able to COMPLETELY retract into the hole. If the ball can not completely retract into that hole, you will get abnormal wear. I have also seen undersized holes that do not allow the detent ball to fit into the hole without jamming.

One thing I have learned recently is that not all Hollywoods are Hollywoods. There were a few ( or more) businesses that had a go at making the Senior Turrets after the patents expired. Some were even produced by others before the patent expired in 1980. Some did it right, some did it wrong. I hope, with the help of many people on this forum, to be able to put that history together. Special thanks to Lubedude, Pressman, ReloaderFred..and many others that have been a great help in sorting this history out.

Harold

TEAM HOLLYWOOD

|

|

|

Reply With Quote

Reply With Quote