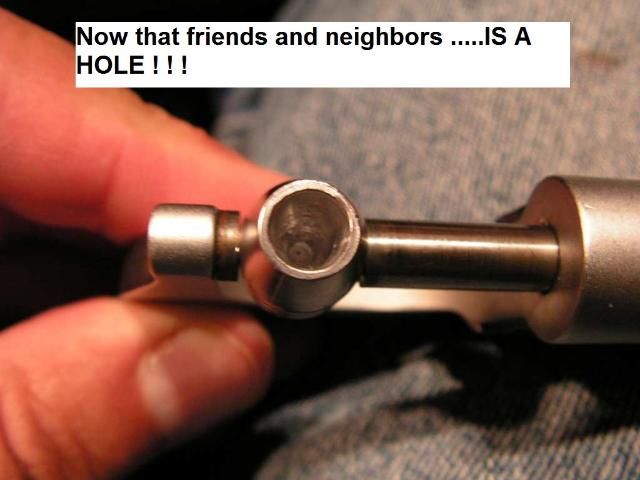

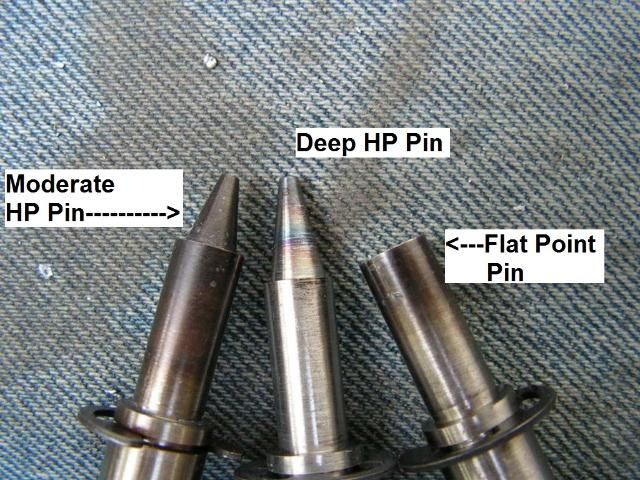

I recently did my first hollow point modification on a 200g .359 round nose. I made a shallow but fairly large hollow cavity. I have seen many molds just the opposite. Deep narrow hollow cavities.

What's the school of thought on this?

I have a 356402 I'm pretty sure I'm going to hollow point next. Just curious which profile I should choose for the 356402.

|

|

|

Reply With Quote

Reply With Quote