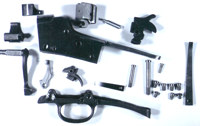

The no pin or screw showing is the Holy Grail of gun design, look at the Shirley post and no screws or pins show. The design I have been playing with has no pins or screws showing and the internals are removed by opening the action lever and a small lever in the forearm then all the parts slide out the bottom in one assembly. Bill T

|

|

|

Reply With Quote

Reply With Quote

Hi Bill.You da man.Outstanding craftsmanship sir.

Hi Bill.You da man.Outstanding craftsmanship sir.