Just responding cause I been on a boat for the past week.

My plan right now is a extra limit switch at the bottom of the stroke. Use a repeat relay at the bottom.

Gonna be a busy week for projects

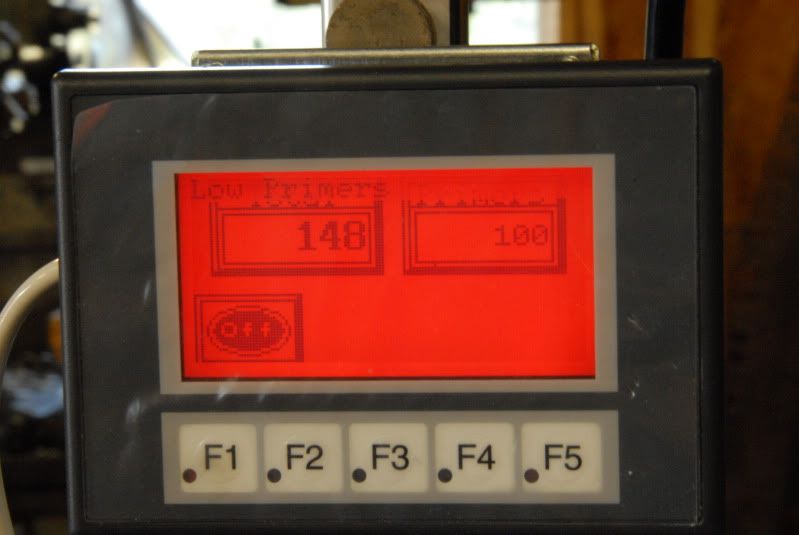

Got the touchscreen, tappers and double acting air cylinder to deal with.

|

|

|

HATCH

HATCH

Reply With Quote

Reply With Quote