My bore is running right at 0.350 (35 Whelen) - is a Bore Riding design supposed to match the bore or be slightly under? I am going to have a mold made and I am not quite sure about this one parameter.

|

|

|

My bore is running right at 0.350 (35 Whelen) - is a Bore Riding design supposed to match the bore or be slightly under? I am going to have a mold made and I am not quite sure about this one parameter.

If you live on the razor's edge and slip, you will die in two pieces

Make the bullet fit the THROAT, and use as large a bulet as Chambers freely and permits extraction of loaded rounds without de-bulleting.. You want the bore riding portion to be lightly engraved and guided by the rifling. About 0.0015 over bore works well if it Chambers freely. Light engraving of an extracted, loaded round is O K.

Thanks. I mic'd the throat, and it is 0.358 and when I called Douglas Barrels they told me the bore should be 0.350 (I get close to that, but don't have calipers with fine enough tips to measure as precisely as I would like, so I took them at their word).

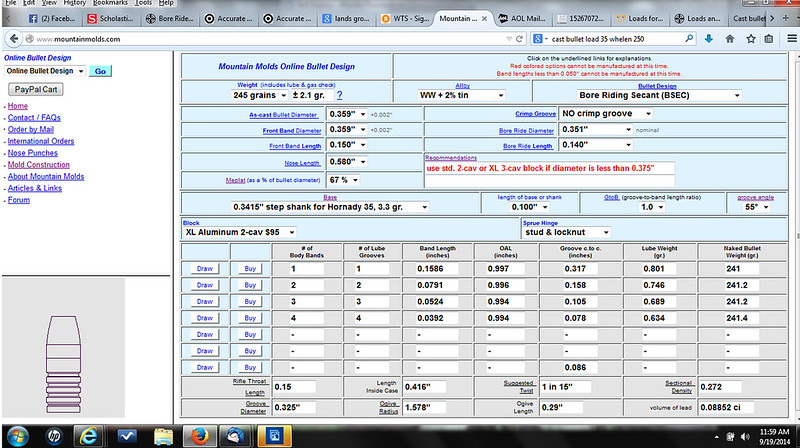

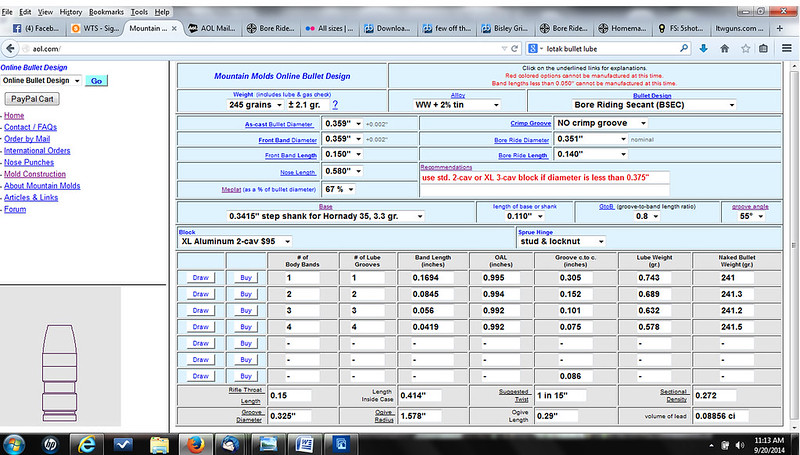

I was thinking of going with a 0.359 as cast diameter with a 0.351 Bore Riding Nose and would then size them to 0.358 for a perfect fit in the throat.

If you live on the razor's edge and slip, you will die in two pieces

You have received good counsel on the issue. The only thing I can add is that bullet hardness can play a part in how much larger than land size you can go with a bullet nose. Soften alloys will engrave easier than harder alloys. It is possible to seat the bullet deeper engraving a rock hard alloy like linotype or some of the water drop stuff so popular now. Always make up a dummy round to test all of this stuff before loading a batch.

Disclaimer: The above is not holy writ. It is just my opinion based on my experience and knowledge. Your mileage may vary.

calipers are for rough measurements.

I can get to about 1/2 thou if a wear some cheater glasses and use a light touch.

the trick is consistently getting them to do what I want.

the other part which I glossed over is the throat fit part.

the boolits design has as much to do with getting the most from it as the diameter does.

you need to find the centerline of the barrel with the centerline of the boolit and mimic the throats shape as closely as possible for the best results whether at pedestrian speeds or when going up the velocity scale.

if you do those two things correctly you would be amazed at how easy it is to push a boolit to 24-2500 fps.

I only used the calipers to try and get the diameter off the lands. I used a Mic for everything else.

Could you elaborate a bit on the Centerline of Barrel/Bullet part? Not sure I follow. As for matching the shape of the throat, are saying that having a front driving band of the correct diameter, and a bore riding nose of correct diameter aren't going to cut it?

This is kinda what I had in mind. It has a large front driving band which gives me a little wiggle room on seating depth (without risk of the base going below the neck/shoulder junction) and allows me to seat it longer if the throat ever elongates...

This Douglas Barrel is a 6 Groove with a 1:12 Twist.

Last edited by 5Shot; 09-19-2014 at 03:05 PM.

If you live on the razor's edge and slip, you will die in two pieces

that's a fair design and should work well.

the centerline to centerline is just that.

- to-

think about a cartridge laying on it's side in the chamber.

it's all at the bottom.

now the trick is to raise everything up so that the centerline of the boolit/case combination is on the centerline of the barrel.

going bigger with the boolit can help get you there [a little] but it then leads to squeezing the boolit down in the barrel and disfiguring it.

you want to get the boolit in the barrel straight and then accelerate it.

the shape of the boolit mimicking the throat directly is what helps insure everything goes forward in a straight line

the case fitting is going to help too.

it's the case [thickness] to chamber neck relationship that really helps put the whole thing together.

Thanks Run...

This is the only Whelen I have (and it is an Ackley version), so cases will probably be neck sized only (and I usually leave an unsized donut at the bottom), so fit of the case should be spot on.

This is an old Remington 721 that Robert Applegate rebarreled for me about 8 years ago. He fit a Douglas Match Grade barrel, that had been rejected by the factory due to a tapered bore. Rob put the taper towards the muzzle so that it would have an increasing grip on cast bullets. It's a 24" tube and Rob gave it a heavy sporter profile and refinished the whole gun in one of the finest bluing jobs I have seen. It is a beautiful piece of work, and I am ashamed to say I have not yet fired it. I never got around to getting a mold from him for it either, but this is its year! I have some LBT Bullets cast up for it from a mold that Lloyd Smale loaned me, and I am going to have this other mold cut this year. I have gobs of powder on hand, but no 3031, which it looks like I should try based on my reading.

Last edited by 5Shot; 09-19-2014 at 08:46 PM.

If you live on the razor's edge and slip, you will die in two pieces

It sounds as if you could benefit from taking a cerrosafe casting of the chamber and throat. That will tell you exactly what diameter boolit you could fit into a loaded round and still get it to chamber. It would also tell you how much freebore you have which is another thing that is good to know so you can decide on seating depth should you wish to do so.

Got a .22 .30 .32 .357 .38 .40 .41 .44 .45 .480 or .500 S&W cylinder that needs throats honed? 9mm, 10mm/40S&W, 45 ACP pistol barrel that won't "plunk" your handloads? 480 Ruger or 475 Linebaugh cylinder that needs the "step" reamed to 6° 30min chamfer? Click here to send me a PM You can also find me on Facebook Click Here.

that little flat area in front of the crimp groove really shouldn't be flat.

it should be a taper right there, that is what fills the ball seat area, and if you get the diameter correct right there it will scuff upon chambering helping align the boolit.

3031 would be a fine powder, but depending on what velocity you plan on achieving it'd be pretty far down my list of choices.

I run 48.5 grs of rl-19 in my 358 win and push a 250 small meplated boolit to about 2350+ fps..

that flat meplat you have would not need that speed to work as a hunting boolit and would perform [quite well] at a more modest velocity.

Thanks Run...

I actually have this one drawn up without a crimp groove - only lube grooves, since I am running out of a box magazine, and I may want to tinker with the OAL some. Do you think I am better off with a crimp groove?

If you live on the razor's edge and slip, you will die in two pieces

if you get the mold to pour super close to your intended size you definately don't need the crimp groove.

crimp grooves are for holding the boolit in place either from recoil or for when moving a round from a magazine or dechambering a tight fitting boolit..

just for fun [seriously] I'd try drawing that one up with just one lube groove.

this would enhance your lead to land ratio some too. [grippage is the technical term]

in many of my bolt guns I only use about .001/.0015 neck tension and don't sweat the boolits moving around in the magazine well.

the thing you gotta think about is,is this a hunting boolit or a target type boolit.

they can cross over some but you have to tailor more to function and a margin for the oh maaan factor in the field and design/load to those conditions.

As for the target/hunting aspect ... 100% hunting. I want it to be accurate, but I don't see myself sitting down (ever) and plinking away with my 35 Whelen AI. I have some nice 223's (would be nice if they were 222's) that fill that niche, and coming up with some cast loads for those is the next project.

How much volume of lube do I need (that will dictate how big I can go with the driving band)? That's the question I guess...

Last edited by 5Shot; 09-20-2014 at 02:17 PM.

If you live on the razor's edge and slip, you will die in two pieces

I would do 1/3rd the length you have there on that lube groove, and only half as deep, and I would move it to the back. A lube groove is a weak point. The nose is going to be twisting when it hits the rifling, and trying to convince the tail to get its lazy butt with the program, and that lube groove is the connection between the two.

I would also take 20-50% off your meplat.

As to your original question, you have to figure that the bigger you have to figure that the grip the neck of the cartridge has on the boolit has a certain amount strength to pull an engraved bore ride nose from the barrel. You want all the contact you can get away with. Typically, I figure that if my bore is .3500 then I want the nose diameter to be that, or .0005 over but no more than that. Otherwise, you're going to cast a batch of bolits that are just a tetch harder than what you usually use, and you're going to have to start carrying a cleaning rod around with you to knock the boolits out of your barrel if you extract a loaded round.

Just my 2cents worth.

Last edited by MBTcustom; 09-20-2014 at 06:50 PM.

Precision in the wrong place is only a placebo.

Taking some time to visit the stickies (of which several participating here have contributed) searching for "throat fit" and "pound cast" will yield lots of info to help you with designing your mould. As mentioned earlier, proper measurements and their relationship to your combo are priority one.

We often "make do" with pretty good, all-around designs...but since you're going with a custom mould you can afford to take a little time to get it right the first time.

you only need the lube groove as deep as the rifling.

slide that lube groove down a bit.

it will also allow you to slide that front drive band down following the lube groove down.

flip the lube grooves basically.

try for about .5 or .6 lube amount.

taper the whole boolit slightly where everything in front of the case slides into your throats shape.

I'm not 100% sure of the angles you need in the whelen, but 2.5* for the first .200 sloping to 2.0* after that for another .200 should be pretty close.

starting out at .359 diameter and following those angles down to your .350 bore diameter.

the smaller meplat goodsteel mentions is because of how the boolit will work on flesh.

if that don't shoot well at 2+k nothing will.

If you live on the razor's edge and slip, you will die in two pieces

that depends a lot on your intended velocity, you can get too good of a result.

if you look in the hunting section, or click on the link in goodsteels sig line, you can follow along with what does and what doesn't work well and why.

also in the 30-xcb thread [in the special projects section] tim has some pics up of how he used a pound slug to determine the shape of a properly static fitted boolit.

once that was done the nose shape was altered slightly for a couple of reasons.

Thanks...

After reading a bit of that thread, I will definitely be heat treating my alloy. I just picked up a nice table top Laboratory Oven off of Craigslist ($50) and I ordered a PID Kit for it. I will be able to dial in my heat treat temp to a constant +/- 1* and get them at exactly the BHN I want every time. I will use the learning mode for the PID to test the slump temp of my alloy and by the time I have that figured out it will be ready to rock.

Last edited by 5Shot; 09-20-2014 at 11:01 PM.

If you live on the razor's edge and slip, you will die in two pieces

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |