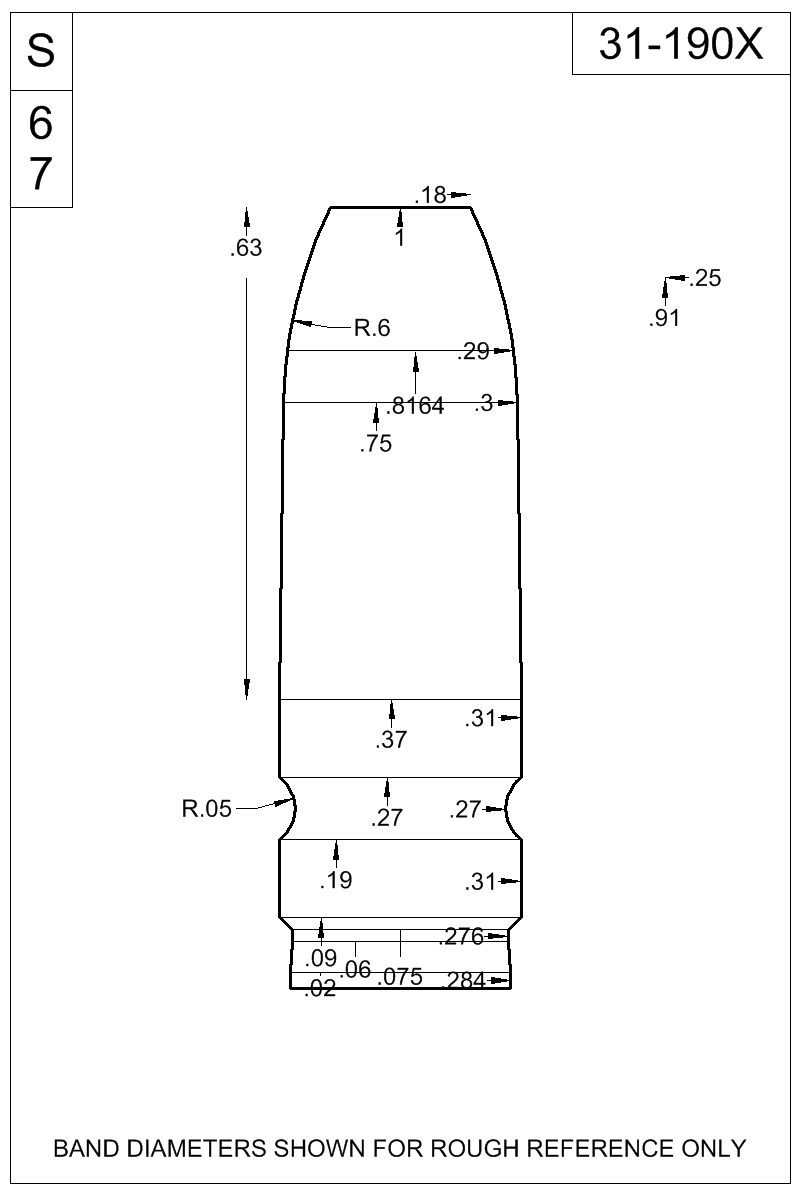

There is a "standard" taper for the 308 chamber and throat I'm sure. Of course who know if you or I have a "standard" throat. The taper of a 30-06 throat is .038" per .001", or thereabouts. I think the 308 is different but how I don't know. If someone would come along and offer information on how to get an accurate measurement of the rifling imprint and taper, or at least what the standard taper should be I think we would be well ahead of where we are. It's been 35 years since I've used any trigonometry and I understand x-thousandths of and inch taper per x-thousandths of an inch better. I'm sure someone here could tell us what it is supposed to be, or maybe Tom could shed some light for us. I was going to say I have no problem in springing for a mold but a mold for one of my rifles won't work in your rifle because of the difference in freebore. I have been studying on a bullet for one of my 30-06's which has .230" freebore and with a bullet of about 180 grains the taper will end at .305" then the nose-proper, which I will hold to .225". The bullet I'm speaking of will give perfect (if there is such a thing) static and dynamic fit in my rifle and have a minimum of .0025 engraving all the way to the taper of the nose. In essence almost the whole bullet will be driving band to some degree.

Rick

|

|

|

Reply With Quote

Reply With Quote