Hello fellow casters,

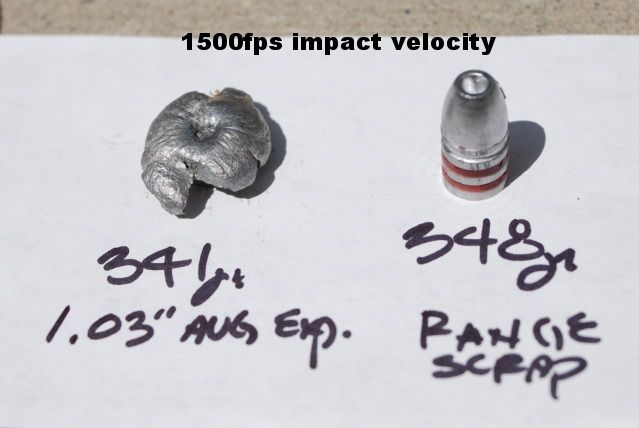

Well, seeing as I have a new accurate mold coming for the 38-55, I decided to HP my current lee 379-250 mold. I may to find some PB gas checks as this mold drops slightly small for my bore. Or, I may even try the powder coating.

Anyways, I took a 1/4" drill bushing and drilled the mold to 1/4". Then I got a 5-16"-18 bolt and cut off to the desired length and turned it down in my drill press using a couple files. Then I measures the distance on my Lee melting pot and cut a pce of dowl the length to help in holding the mold at the correct height.

I'm smelting some lead now from WW's. Once done I'll fire up the pot and give it a go.

|

|

|

Reply With Quote

Reply With Quote