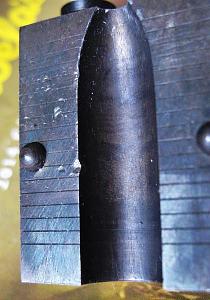

Today I received my new to me custom Tom Ballard .450 adjustable Paper Patch mold. The mold is damaged and I would really appreciate it if someone here would please fix it. I won't return it because it's too difficult to replace and I purchased it from a friend for a reasonable price. He purchased it second hand also. The mold was disrespected either by dropping it or something fell on it, or improperly packaged for shipment. All pure speculation on my part. The leading edge has a divot that protrudes into the cavity. So here are the photos and I'm willing to be more than fair to have this mold repaired. Your expertise is a wonderful resource. I know in theory how to use a bullet to spin with a polishing compound but I won't risk screwing it up. I have many bullets cast with this mold to send with the mold that were likely cast before the damage occurred. Thank you.

|

|

|

Reply With Quote

Reply With Quote