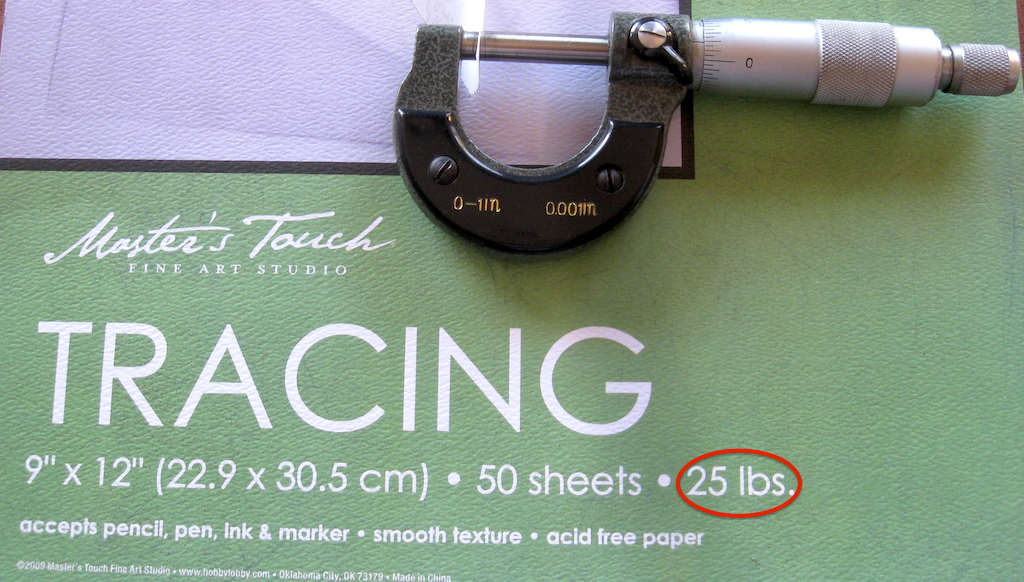

I have not started patching for my Marlin in .35 yet but am patching .30-30 and .30-40 with great success using tracing paper. No luck with other papers. My loads are full house loads intended for hunting and give excellent accuracy. This 1900 vintage 1895 does these groups at 100 yards with an Accurate 215gr bullet sized .3035 and damp patched with 2 wraps .002 tracing paper. No further sizing is done. I don't know if any paper is hanging in the lube groove but I am not worried about it.

By the way, I really like your 81.

|

|

|

Reply With Quote

Reply With Quote