Kind of a unique title , right ? I thought that one might get your attention.

I have thirty +, .30 cal. molds right now. Since my molds are made by Cramer, SAECO, RCBS, Lee, Lyman/ IDEAL, the variations in drive band diameters , gas shank diameters, and nose diameters are " all over the place ".

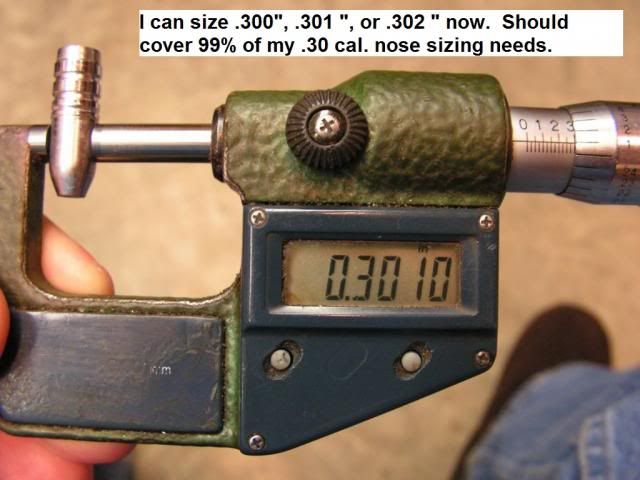

Nose diameters of the molds described above vary from .299" - .304".

I have .30 cal. rifles that if you try and chamber a round with a .304" dia. nose, you won't ever get the bolt closed. In a hunting situation or self defense situation , you could stick the bullet ( with an over sized nose ) in the bore, when you withdraw the case, powder will fill the chamber and magazine box....a real mess. Basically rendering the weapon un-usable until you can get a cleaning rod to tap out the stuck bullet and get everything cleaned up. If you've loaded very many cast rifle bullets, you have probably already experienced what I describe above. If the nose is sized properly and you have the correct OAL for your loaded rounds, this will never happen. The beauty of a properly sized nose on your rifle bullets is IMPT ! for proper chambering and also an aid in the accuracy dept.

My .30 cal. rifles each like a different bullet dia. on the drive bands. However some of them have tight bores and won't tolerate a " fat nosed bullet." If the nose of the bullet gets much over .3015" there will be problems in chambering the round. I have a Springfield 1903 Sporter in .308 Win. that isn't very tolerant of cast bullets with a nose of over .301". I hope you are able to see why I ( and possibly you ) need the ability to control nose diameters.

I've always read about sizing the nose of a cast bullet, but considering the fact that RCBS, Lyman, etc . didn't sell the nose sizing dies , I just never got serious about the concept.

3 years ago, I had Buckshot make a .302 nose sizing die for me. It was solid steel that fit the Lyman 450 with the threaded ring that holds the sizer die in place. It has been useful, however I found that I also needed a .300" and a .301" diameter nose sizing die.

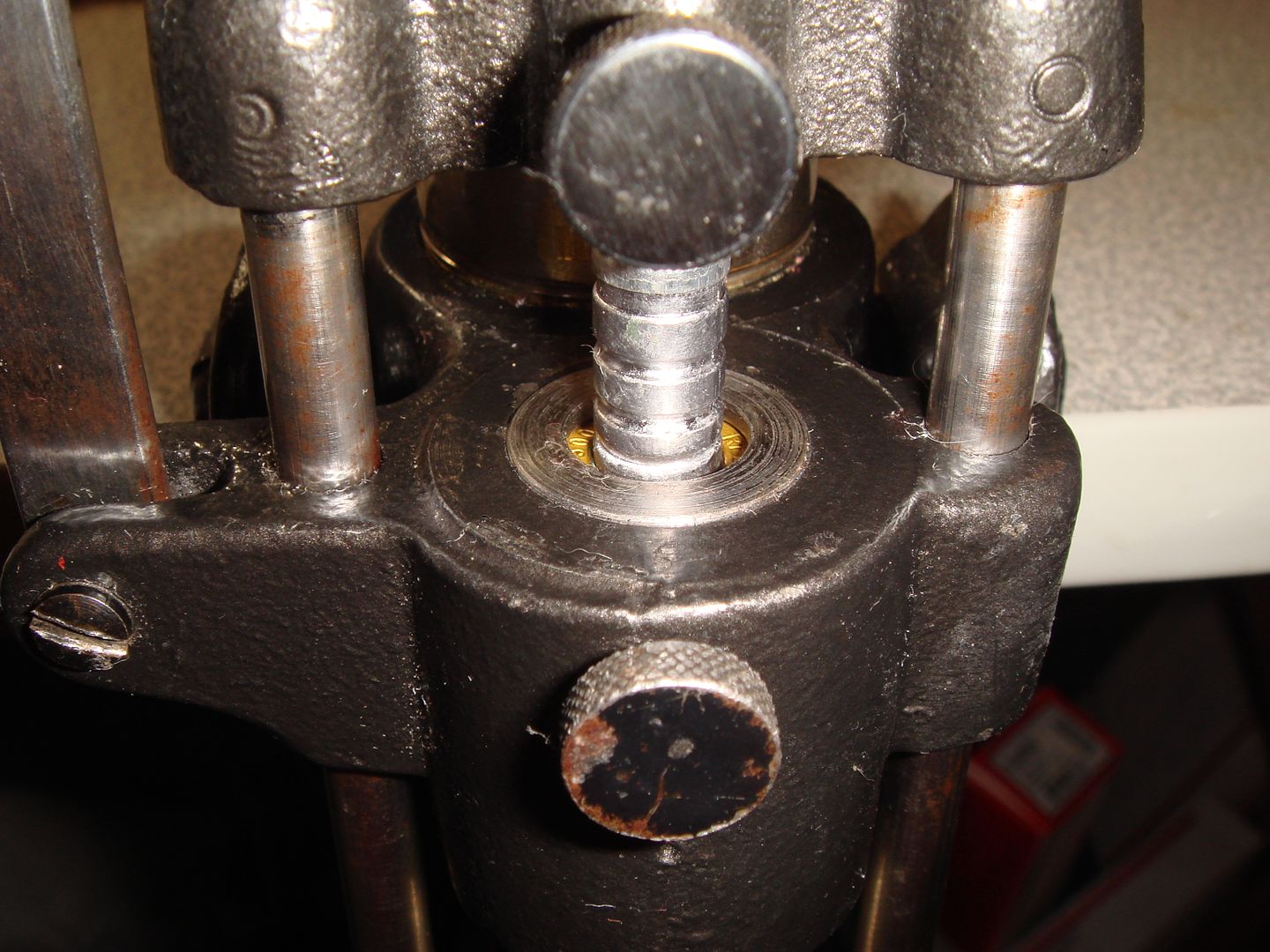

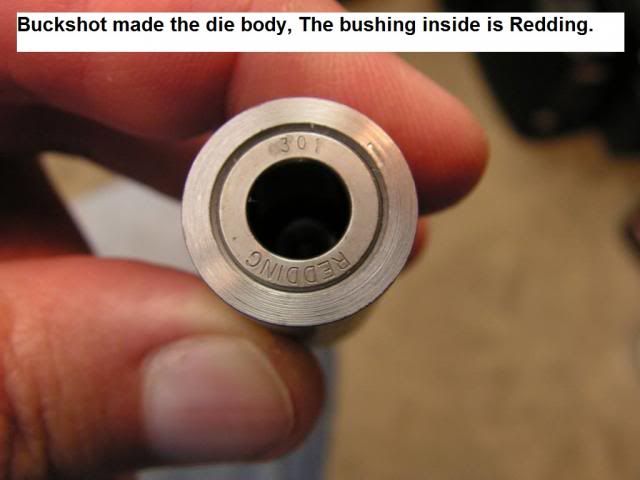

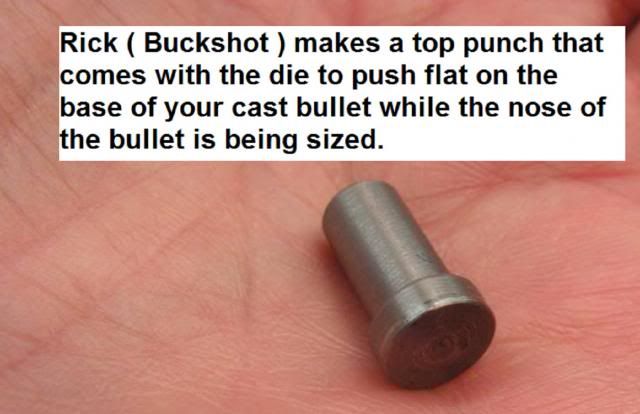

About 3 weeks ago, I contacted Rick ( Buckshot ) about making me a cast bullet nose sizing die that would take the Redding bushings . I received the die a few days ago. It works flawlessly. This die takes the Redding sizing bushings that are available from MidWay, Graf's , etc.

Here are the bushings, I chose to buy the heat treated, hardened steel bushings since they are about 60% of the price of the Nitride ones. A thin film of lube on about every 3rd bullet going into the sizer ring is all this is needed with these steel bushings. They are polished " mirror smooth".

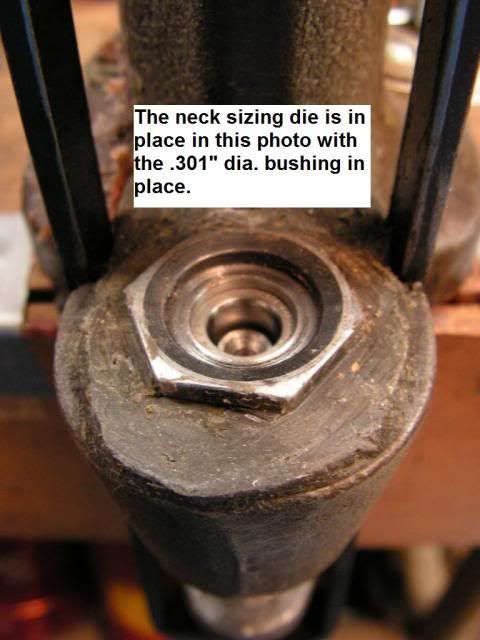

Here is Buckshot's bushing die with a Redding .301 sizer ring in place and ready to be installed in my Lyman 450 :

|

|

|

Reply With Quote

Reply With Quote