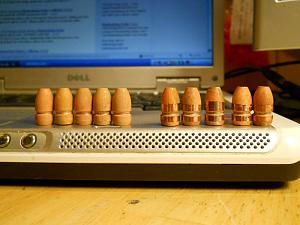

I just cast 500 lyman-#356637 147gr bullets, ---sizing to .357"

ive been doing some home copper electroplating on them, ive discover something about how much of a difference there is between these boolits.

When i run a copper plated bullet through the .357" die it goes right through! even if it's a fatty!

my little work table flexes when im lube sizing, and if the bullet was on the big side i thought i should put a better top on my small work bench, when im sizing the copper plated one's, my table does not bend, they just size!

very little plating comes off during sizing, so im thinking these are going down the barrel much better Than i first imagined.

|

|

|

Reply With Quote

Reply With Quote