i decided to go ahead and purchase a 30-06 (edit: and a 7mm-08) at the end of the year so i can deer hunt with my son next year who will be living in Wyoming... my reason as that my .243 Win was fine here for our smaller California Mulies in the southern Sierra, but the winds and larger Rocky Mountain Mulies could not be had as easily with that caliber... anyway, right or wrong that was my story and i am good to go

so, i am going to start planning to make some 30 caliber dies this winter (edit: and 7mm dies)... not quite as easy to make as 9mm to .40SW, or .22LR to 0.224, at least that is how it looks from here at the beginning of this project... i like to swage mainly because it gives me a feeling of independence from market or governmental forces and shortages, and that is just plain feels good to shoot homemade with dies you made... with that perspective in mind i would like these 30 cal swaged bullets to follow these parameters:

1) this will be a hunting bullet and plinking/practice, not BR... looking at 150gr to 180gr, not sure on exact size just yet... also want to flexibility to make 125gr for 300 Blackout... MOA at 100 yards would be the goal...

2) Use readily available jackets - for me this means range brass... in particular i like the idea of drawing down 9mm cases... i know you can use soft copper tubing to swage or draw the jackets, but now i am dependent upon the availability of soft copper tubing which is abundant right now but it may not be at some point in time... but it seems like 9mm range brass is far cheaper and abundant... for example, you can buy soft copper tubing in bulk for about $1 per foot, and perhaps you can get 11 jackets per foot, that is about $0.09 per jacket (not including trimming, and associated costs for that)... you can find used 9mm brass in bulk for about $0.03 a case... seems like case closed to me! hopefully, once the 9mm jacket is drawn down to size it wont have to be trimmed, but that is yet to be determined... also, because untrimmed brass will be used, with the casehead not removed, this precludes a BT and a FB design will be used (i think it would be difficult to form a BT base on a bullet casehead)... bullets lengths are approximately 1.2", 9mm bras is approximately 0.72", i am not sure how much they lengthen when being drawn...

3) use readily availabe cores - i dont want to be dependent upon a source for lead wire, so i will be casting boolits to use as cores... i think a 7mm rifle mold would work great... a 0.285 diameter bullet should drop right in a 0.306 jacket, and the 120gr cast boolit can be trimmed to size for whatever weight swaged bullet is being made... a 120gr + 60gr 9mm jacket = 180gr 30 cal swaged bullet...

4) this will be done using a standard reloading press, in particular my RCBS RC Supreme will be used... i cant afford a dedicated swaging press as these die sets home-made in part due to economy...

to get started seems like the biggest challenge, outside of the point forming dieis making the draw dies... these will be similar to the push thru derimming dies used for 22LR... 9mm case OD is approximately 0.380, and it needs to be drawn down to 0.305 or so to allow for core seating to 0.307 and then point forming to 0.308... so i need to draw down 0.075... obviously this can't be done in 1 step, manually at least on a swaging press! perhaps this can be done in 3 or 4 steps? i understand that the brass gets work hardened each time it is drawn, so will it need to be annealed after every 1st or 2nd draw? can i use just one punch tapered to about 0.285 for the drawing?

alright, anyone who has thought about doing this or done this please weigh in... thanks

here is a great thread on this from "Mountain Prepper":

http://castboolits.gunloads.com/show...to-308-jackets

UPDATE August 2014:

here are the finished 7mm 135gr home swaged bullets (left is Speer 145gr I was trying to copy, right is my version):

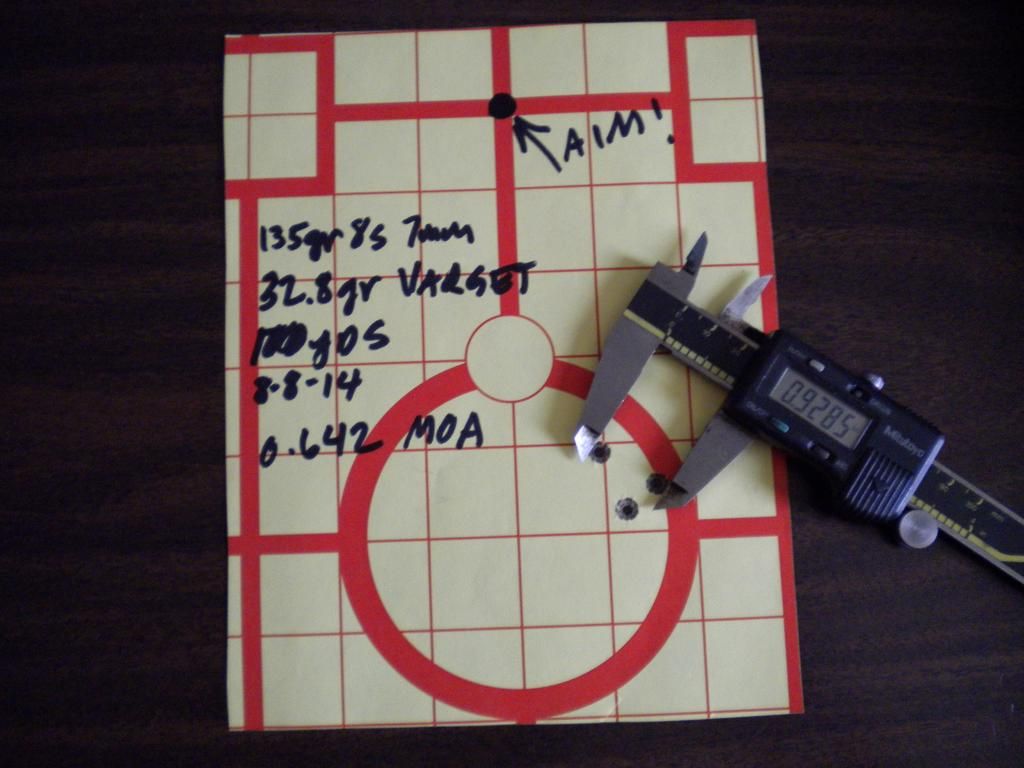

and they grouped in at under MOA!!!

.

|

|

|

Reply With Quote

Reply With Quote