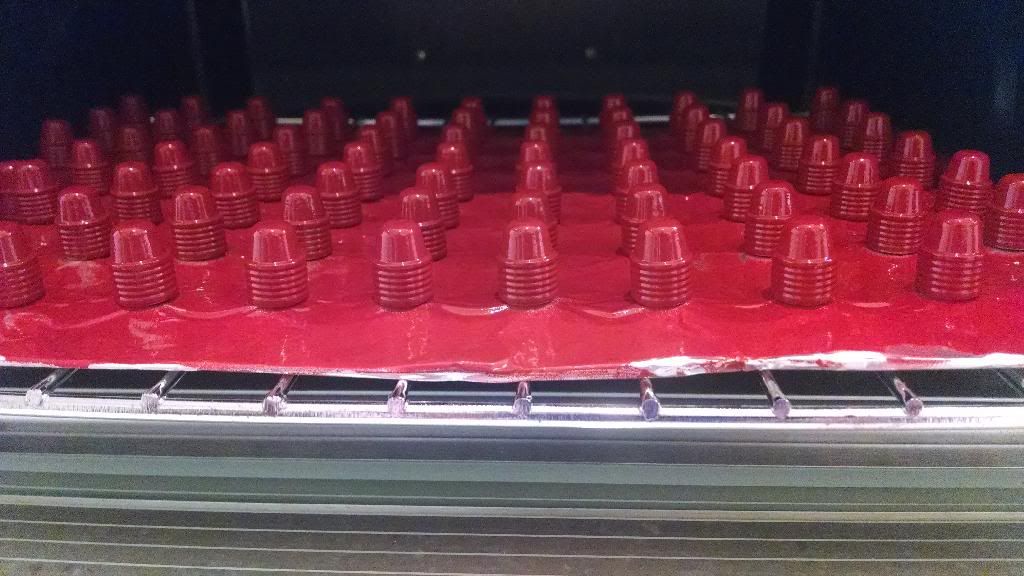

First stumble in the learning process... The sheet metal is plenty strong and hardly bows when picked up with the weight of the bullets on it. But it does slightly bow and bullets balancing on hex nuts glide right across non stick foil. Go figure. I need to do something to brace the sheet metal so it is solid enough to not bend at all. And the rack of freshly sprayed bullets needs to be right next to the oven or as close as possible to not risk bullets falling over or sliding. I need to find a way of mounting small handles on each side to pick it up careful enough to not tilt it at all. And then it needs to be easy enough to slide into the oven. Enough about the stupid rack...

Second stumble in the learning process... The spray gun is rated at 10 - 30 PSI and with the regulator set at 25# I had some intermittent flow issues. One second it was coating too thick and then not at all. This first batch isn't going to be perfect but once again this is the learning phase. It may just be the pressure being lost from the tank to the gun and the gun isn't really getting 25# to work with. I will dial up the pressure to 30# next time. But enough talking, we want pictures of results, right???

This is them freshly sprayed:

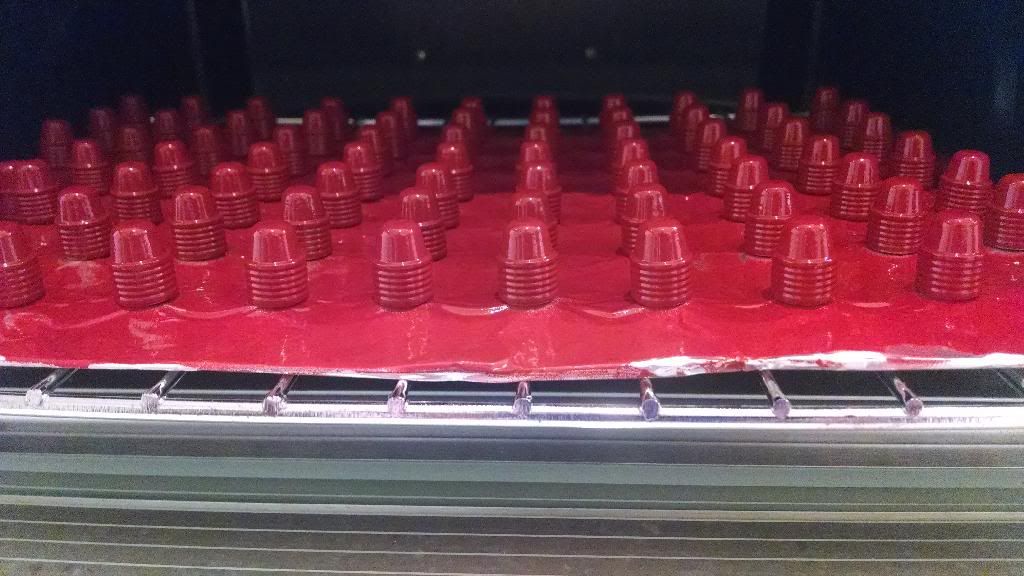

I wore a dust mask and that isn't going to cut it. I need to open the garage door and buy a real mask before I do this again. This stuff really hangs in the air. Once I get the powder flow just right there will be less waste but this time there was a red cloud. Yuck.

This is them fresh from the oven:

It's already a night and day difference in the quality of coating. They lose the dull sheen and it's finally a glossy coating. They feel so much more slick to the touch. With this method the bases aren't coated or at least not with this tray but I'm not worried about that. I'm just in this to avoid bullet lube and bullet lube smoke. The cleaner bore is just an added bonus. The low cost of the HF powder is what drew me back to this and the much better results with the ES spray gun is what made me break down and try this method. I know with this first trial run I used way more powder than I should have but I know I will get better at it and use less. That's the only way I will really be able to tell about cost effectiveness of this method for sure. I also need to try this method with rifle bullets since the finish is so much more even than any other method including the epoxy paint tumble. But for this being the very first trial run I still think these look awesome enough that I will continue to work at this.

This would be the reason for the hex nuts. This one fell off the nut and sat on the tray with the excess powder:

This is a dry tumble vs. ES comparison with the ES in front:

I cannot express enough how good these look and feel compared to anything else I've tried so far. The finish comes out so perfect!!!

Reply With Quote

Reply With Quote