I got a HP 6gal 1.5hp compressor when I started PC. It does a great job but isn't overkill or large, also just right for tires-

http://www.harborfreight.com/2-horse...sor-67696.html

It comes on when tank pressure falls below 100psi but there's plenty of air in the tank for uninterrupted use.

I put a small regulator right at the air input to the gun to regulate 8-10psi at the point of use, rather than at the supply side of a hose-

http://www.harborfreight.com/14-mini...uge-68226.html

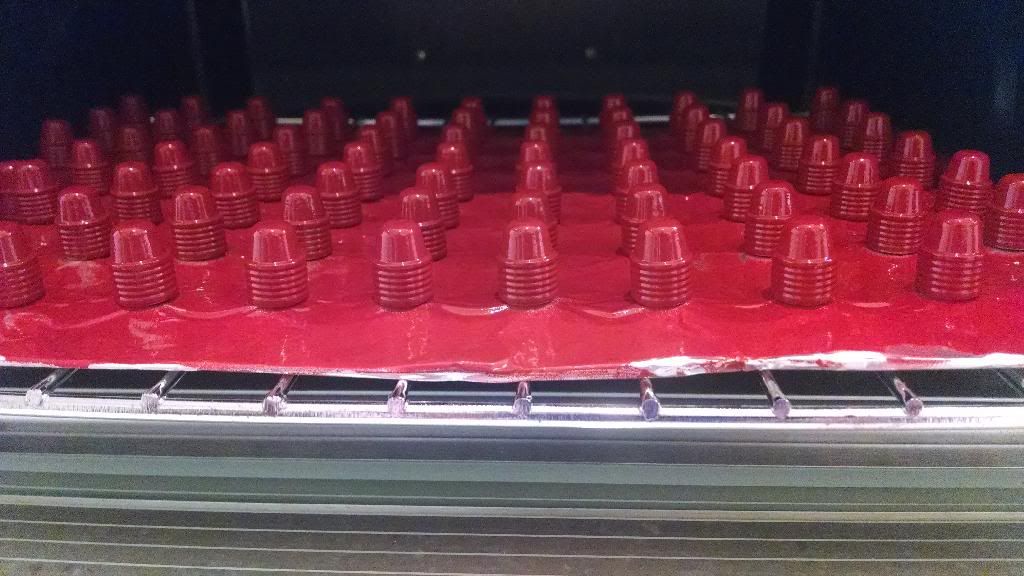

I took off the bracket and used a coupler. It's true the low pressure PC works at is at the bottom of the scale but it still allows good adjustment and the knob locks in position after tweaking. It is visible in these pics-

|

|

|

Reply With Quote

Reply With Quote